2022-05-31 17:51:05

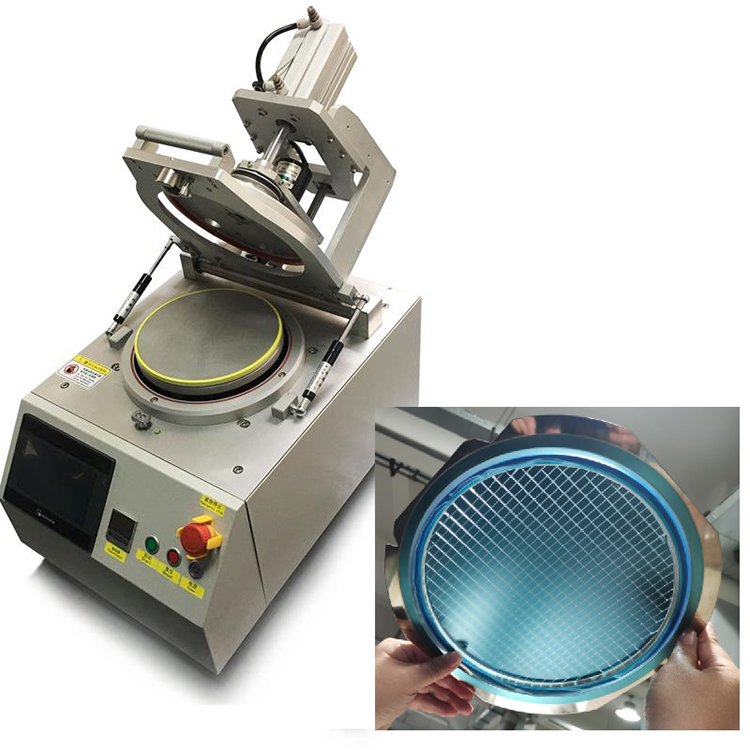

Wafer film expander is a film expander clamping device, including upper base, lower base, upper pressing plate and lower pressing plate. A guide rod and a driving rod are arranged between the upper and lower bases. Both ends of the guide rod are vertically connected with the upper and lower bases respectively. The rotation of the lower end of the drive rod is limited in the lower base, and the upper end runs through the upper base and is fixedly connected with the output shaft of the drive motor though the coupling. The rod body of the driving rod is provided with a first rod part and a second rod part contrary to the rotation direction of the thread. The side of the upper pressing plate and the lower pressing plate are respectively connected with a guide sleeve and a drive sleeve. The guide sleeve is arranged outside the guide rod. The driving sleeve is connected with the outer part of the first thread or the second thread. The upper and lower pressing plates are respectively provided with pressure frames, and the radius difference between the two pressure frames is used to clamp the blue film of the wafer. The equipment conforms to the utility model is reasonable in structure design. It uses the screw drive principle to drive the upper pressing plate and the lower pressing plate close to each other or away from each other. It has the advantages of fast and accurate, and ensures the efficiency of film expanding.

Note: when selecting Manual Crystal Expander, please provide the size of the inner and outer ring of wafer expander and the type of film used. Please contact us: Shenzhen Deshengxing Electronics Co., Ltd. +186-18924372460 Jennifer