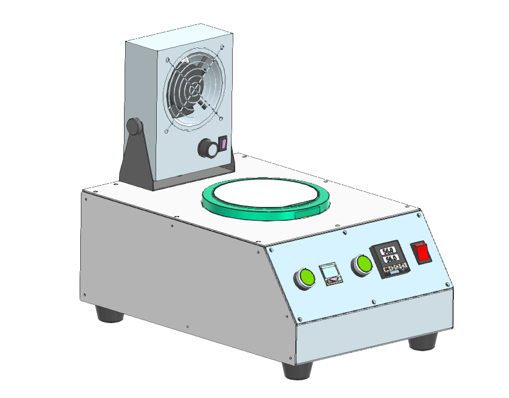

The DSXUV 6 inch frame film manual wafer tearing machine is equipped with a high-precision ceramic chuck to ensure stable wafer fixation during operation. Designed for manual film tearing, it offers reliable performance and precise control. This machine is suitable for semiconductor wafer processing and packaging applications.

model no. :

DSX-025-165Brand:

DSXUVColor :

Whiteport of dispatch :

Shenzhenoriginal region :

ChinaLead Time :

15daysDSXUV 6 inch Frame Film Manual Wafer Tearing Film Machine With Ceramic Chuck

6-inch Wafer Film Tearing Machine, Ceramic Disc Vacuum Adsorption Laboratory, Small Semiconductor Packaging Film Tearing Equipment

|

Parameter reference |

Parameter |

Parameter |

Parameter |

|

Model: |

DSX-025-165 |

Fixation Method: |

Vacuum Adsorption |

|

Chuck Material: |

Ceramics |

Heating System: |

Have |

|

Atmospheric Pressure: |

0.6-0.8Mpa |

Total Power: |

500W |

|

Voltage: |

220V |

Positioning Method: |

Small Tablet Engraving Line |

The main features of the manual 6-inch wafer tearing machine can be summarized as follows:

1. Ionic fan: used to eliminate static electricity, prevent the wafer surface from adsorbing dust or film debris, and ensure the cleanliness of the film tearing process.

2. Ceramic tray: Provides a flat, high-temperature resistant, and corrosion-resistant working platform to protect wafers from damage during the film tearing process.

3. Temperature control switch and temperature control display: It can achieve temperature adjustment and real-time monitoring, adapt to the temperature requirements of different film materials, and improve the quality of film tearing.

4. Vacuum display and vacuum switch: The wafer is fixed by vacuum adsorption to ensure its stable position and safe and reliable operation during the film tearing process.

5. Power switch: controls the power on and off of equipment to ensure safe operation.

6. Manual operation mode: suitable for small batches or experimental environments, flexible operation, and relatively low cost.

Application area:

1)Semiconductor Manufacturing and Packaging

2)advanced packaging

3)Optoelectronics and Display Field

4)For Electronic Mechanical Systems and Research

5)Solar photovoltaic field

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

DSXUV 12inch Semi-automatic Wafer Mounter Film Sticking Machine

This equipment (lamator) is mainly used for 12 inch Si wafer BG film coating. No burrs, no bubbles. The wafer type is dummy wafer. This semi-automatic film sticking machine is suitable for applying film to products such as wafers, semiconductors, ceramics, and glass. It is a device used for film coating processing, specifically designed to precisely adhere thin film materials to the surface of wafers. It combines the characteristics of manual operation and automatic control, providing higher film application accuracy and efficiency while maintaining operational convenience.

Semiconductor Double Film Wafer Chip Laminating Machine

Semiconductor Double Film Wafer Chip Laminating Machine

Wafer Frame Film Mounter Machine can place UV tape and blue film at the same time for using.

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

Manual Wafer Laminating Machine Wafer Backgrinding Mounter 6 8 12 Inches

6/8/12 inches Manual Wafer Laminator series is a fast and efficient sticking film machine, special designed for wafer, glass, LED PCB, and ceramic cutting process.

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

DSXUV-Wafer-M8 8 Inches Manual UV Tape Wafer Mounter

Wafer Frame Film Mounter is a machine that fixes a wafer and a ring together through a blue film or UV film.

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

DSXUV-Wafer-M6 6 Inches Semiautomatic Wafer Mounter For Dicing UV Film Cutting

Wafer Tape Laminating Machine is a machine that fixes a wafer and a ring together through a blue film or UV film.

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

Customized Glass Filter Semiconductor BG Film QFN Lamination Equipment

DSXUV accept customized various glass material film laminating machine, various UV tape blue film BG film laminating systems.