2025-04-11 17:42:25

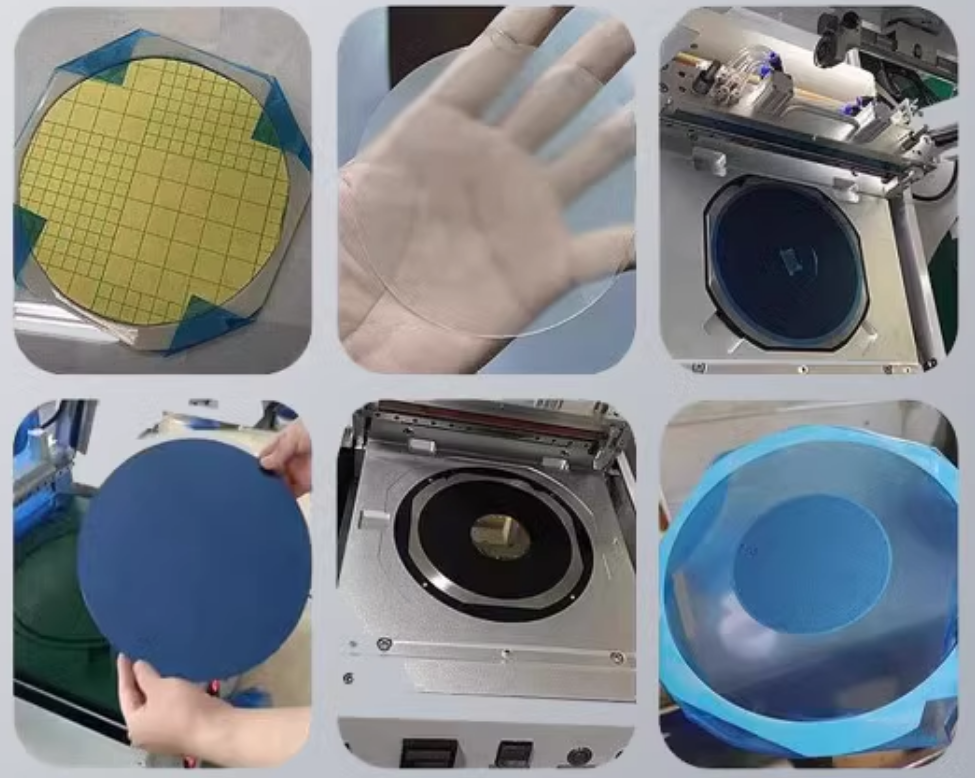

Wafer Film laminator machine is a widely used equipment in industries such as electronics, communication, and semiconductor. It is mainly used to stick protective or explosion-proof films, ensuring that there are no bubbles or scratches during the film sticking process.

The working principle of the film wafer mounter machine mainly includes the following steps:

Preparation: Install the roll shaped protective film onto the film wafer laminating machine and place the product on the indexing plate fixture for positioning.

Film application process: After starting the film wafer mounter machine, the machine will automatically apply the protective film accurately to the surface of the product. During this process, the film applicator ensures that the protective film is not deformed or has large bubbles, while also avoiding dirt and scratches on the surface of the product.

Product remove: Products with protective film attached will automatically rotate the indexin

plate. When the indexing plate rotates to the material retrieval station, the product will be retrieved.

Wafer laminating machine operation attentation:

When operating the film wafer laminator machine operation monitoring: After the machine is started, it is necessary to master the speed adjustment of the drum, temperature control of the drum, and temperature control of the drying oven, and strictly control the speed and temperature of the equipment.

Film testing inspection: After the equipment is started, it should run empty for 3-5 minutes and test several films to ensure they meet the requirements before mass production.

Operation safety: During operation, hands should only be at a distance of 30 centimeters from the drum and should not enter dangerous areas. Clothes and long hair must be tied tightly and not scattered.

Fault handling: If the work is completed or there is a malfunction or abnormal situation, the machine must be stopped first, reported to the supervisor, and repaired.