2025-08-12 09:55:17

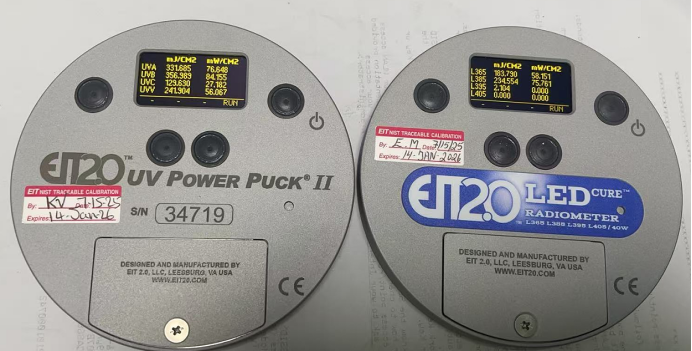

American EIT four channel energy meter LEDCure Four Band professional testing UV LED curing machine.

This instrument is a detection instrument launched by EIT in the United States this year (end of July 2025) specifically for monitoring the energy and illuminance values of UVLED light source systems. This UV energy meter is different from the previously released LEDCure Four Band Profile version. This is a UV energy meter without a Profile version. It is also relatively affordable in terms of price.

It is an honor for our company (Shenzhen Deshengxing Electronics) to place an order for this instrument for users on the occasion of the product's release. We compared the UVLED system with the mercury lamp light source UV curing machine and conducted tests on both devices. At the same time, we also compared the data of EIT POWER PUCK II and LEDCure Four Band instruments under the same conditions for mercury lamps and LED light sources, respectively. Curious users who need to know about this UV energy meter are advised to consult the customer service of Shenzhen Deshengxing Electronics Co., Ltd. in advance.

Product parameters:

Brand: EIT

Origin: United States

Model: LEDCure Four Band (without Profile)

Channel: Four band monitoring is available with L-365, L-385, L-395, and L-405 responses. Function: Monitor the UV energy and illuminance values of the UVLED curing machine, including irradiance (W/cm2) and Energy Density (J/cm2)

Range: 40W

Comparison data test results of EIT Power Puck II and LED Cure 4 Brand in the United States.

1. Test model: UVLED 365nm desoldering machine The comparison data of the same position is as follows:

Test model: 1KW desktop high-pressure mercury lamp UV curing furnace The comparison data of the same position is as follows

The data reveals significant discrepancies. The U.S.-based EIT Power Puck II is typically used for high-pressure mercury lamp measurements, while the LED Cure 4 Brand was specifically developed for UV LED curing systems. As the two tested devices differ fundamentally in design, their measurement results naturally diverge. Therefore, when selecting measurement tools, it's crucial to match them with specific application scenarios and equipment types to ensure data accuracy and reliability. Different devices exhibit markedly varying compatibility with measurement tools, making informed selection essential for optimal performance.