As electron component, Light Emitting Diode-LED has appeared more than 40 years. But for a long time, limited by luminous efficiency and brightness, Light Emitting Diode-LED has being a indicator light. Until the end of the last century, the technical bottleneck was broken, produced high brightness and high efficiency LED and UV LED, which extended its application scope to signal lamp, city night view project, full color screen, etc., and provided the possibility of lighting source. With the increase of LED application scope, it is more important to improve LED reliability.

LED has the advantages of small volume, low power consumption, long life, environment protection, high reliability. In the actual production and development process, the reliability level of LED Chip needs to be evaluated through the life test, and improves the reliability level of LED Chip through quality feedback to ensure the quality of LED Chip. In order to realize the industrialization of the whole color LED, the conditions, methods, means and devices for the life test of LED Chip are developed, so as to improve the scientific nature and the accuracy of the results.

Determination of Life Test Conditions

Under the specified working and environmental conditions, the work of electronic products is called life test, also known as durability test.

With the improvement of LED production technology, the life and reliability of the products have greatly improved. The theoretical life of LED is 100,000 hours. If it is still used life test under conventional normal rated stress, it is difficult to make a more objective evaluation of product life and reliability. However, the main purpose of experiment is to understand the attenuation of ultraviolet LED Chip optical output by life test, and then to infer its life span.

According to the characteristics of UV LED Devices, after comparison test and statistical analysis, the life test conditions of microchips are specified under 0.3x ~ 0.3mm2 in the end:

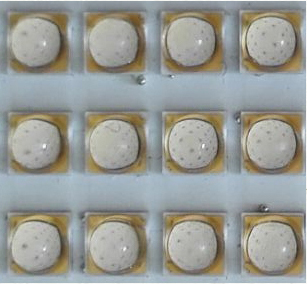

1.The sample was randomly selected, and the quality was 8 ~ 10 chips, made up ф5 single lamp.

2.The working current was 30mA.

3.The environment condition is indoor temperature (25℃±5℃).

4.The period of test was divided with 96 hours, 1,000 hours and 5,000 hours.

The 30mA working current is 1.5 time of rated value, is the life test of increasing electrical stress. Its result cant not represent the real life expectancy, but there’s a lot of reference value. The life test was made by the epitaxial slices, was random extraction of 8 ~ 10 chips in one of the epitaxial slices, conducted 96 hours life test, which the result represented all the epitaxial slices produced in this production batch.

In the generally believed that the test cycle of 1,000 hours or above is called long-term life test. When the production process is stable, the life test frequency of 1,000 hours is low, and the life test frequency of 5,000 hours is lower.

Procedures and Precautions

For LED Chip life test samples can be used a chip, which commonly known as a naked crystal, also can be used the device which is through encapsulated.

Using the naked crystal form, the external stress is small and easy to dissipate heat. Therefore, the light attenuation is small, service life is long, there is a gap to the actual application, it can be adjusted by increasing current, but it is better to use single lamp device directly.

The life experiment of single lamp device made the factors of photo-aging of devices complicated. There may be a chip factor, there are also encapsulation factors. In experiment process, taking a variety of measure, reducing the impact of encapsulation, improving the details of the accuracy of test results, only in this way, the objectivity and accuracy of the test results are guaranteed.

1.Sample Extraction Method

The life test can only use the sampling test method, which has certain risk.

Firstly, the product quality has a certain degree of uniformity and stability, which is the premise of sampling assessment. Only if the product quality is uniform, the sampling is representative.

Secondly, because the actual product quality has certain discreteness, we took the method of partition random sampling to improve the accuracy of life test results. By seeking for the relevant information and conducting a large number of comparative experiments, we proposed a more scientific sample extraction method: according to its position in the epitaxial chip, the chip is divided into four zones, with 2 ~ 3 chips in each region, and 8 ~ 10 chips in total. For different devices has different results of life test and even contradictory. We stipulated a method for the life test that is with 4 ~ 6 chips in each region, and 16 ~ 20 chips in total, tested in normal conditions. Only the quantity was tightened, not the test condition.

Thirdly, in generally speaking, the more the sample, the smaller the risk, the more accurate the result of the life test results. However, the more samples were sampled, it must inevitably result in the waste of manpower, material resources and time, and the test cost must go up. It is what we’ve been working on how we deal with the relationship between risk and cost. Our target is to maximize risk at the same cost by taking a scientific sampling approach.

2.Photoelectric Parameter Test Method and Device Distribution Curve

In the life test of LED, the test sample was screen by photoelectric parameter test at first. Abnormal photoelectric parameters or devices were eliminated. The qualified products shall be numbered and put into the life test. The test should be carried out after the continuous test, to obtain the life test results.

In order to make life test results objective and accurate, except for measure the instrument well, it is also stipulated that the same test instrument will be used before and after the test, which is to reduce unnecessary errors. This is particularly important for light parameters. In the early stage, we used the change of measuring device light intensity to judge the condition of light. The axial light intensity of the general test device, for a device with a half=angle of the light distribution curve, the magnitude of the light intensity various dramatically with geometry, measuring repeat-ability is weak, which affects the objectivity and accuracy of the test results. In order to avoid this situation, it is adopted a large angle of encapsulation, and chosen no reflector cup holder, to eliminate the effect of reflection cup with light, to eliminate in the influence of the optical performance and improve the accuracy of optical parameter test. The subsequent adoption of light flux measurement is verified.

3.The Effect of Resins on Life Test

Transparency of the existing epoxy encapsulation material is reduced by ultraviolet radiation, is the photo-aging of polymer materials, is the result of a series of complex reaction involving ultraviolet radiation and oxygen. It is generally believed that the automatic oxidation process caused by light. The influence of resin deterioration on life test results mainly reflects 1,000 hours or more long life test. At present, the results of life test can be improved by reducing ultraviolet radiation as far as possible. In the future, it can also be used to select encapsulated materials, or to check the optical decay value of epoxy resin, and to exclude it form the life test.

4.The Effect of Encapsulation Process on Life Test

Encapsulation process has great influence on the life test. It was used transparent resin,which can directly observe the internal fixation and bonding by microscope for failure analysis. But not all the encapsulation defects can be observed. For example, the quality and process of bonding solder joints are closely related to temperature and pressure. Too high temperature and too high pressure will cause the deformation of the chip to produce stress. Thereby, introducing dislocation and even dark crack, which effects the efficiency and the life of the light.

Attractive stress change of leading bonding, resin encapsulation, such as heat dissipation, expansion coefficient are the important factors which are influencing the life test results. The results of its life test are worse than that of the bare crystal life. However, for the low current power chip, the quality range of the assessment is increased, and the life test results are closer to the actual usage, which has certain reference value to the production control.