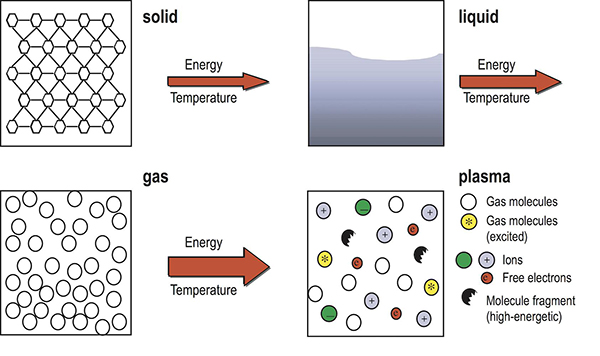

Adding more energy to a gaseous substance, such as heating, will create a plasma. When they reach the plasma state, the gaseous molecules fission into a multitude of highly active particles. These splits are not permanent, but once the energy used to form the plasma disappears, the particles recombine to form the original gas molecules. Different from wet cleaning, the mechanism of plasma relies on the“activation action”of the material in the “plasma state”to remove the object surface stains. From the point of ciew of various cleaning methods, plasma cleaning is also the most thorough stripping cleaning method among all cleaning methods.

What is Plasma Cleaner? Plasma cleaning generally uses laser, microwave, corona discharge, thermoelectric ionization, arc discharge and other ways to excite the gas into plasma state.

In practical use, considering the production cost and practical stability, purified ADC (compressed air), O2, and N2 are generally used, while argon is only used in some special occasions. This is achieved by using the motion of the free radicals of oxygen in the plasma to achieve a hydrophilic surface. When this hydrophilic is formed, the plasma oxygen free group combines with the carbon on the substrate surface to product CO2, thus removing organic matter.

Efficient Plasma cleaning technology for surface treatment can remove organic pollutants on the surfaces of metals, ceramics, plastics and glass, and can significantly change the adhesion and welding strength of these surfaces. The ionization process can be easily controlled and repeated safely. It can be said that effective treatment is crucial to improve product reliability or process efficiency, and plasma technology is also the most ideal technology at present. Through surface activation, plasma technology can improve the properties of most substances : cleanliness, hydrophilicity, hydro-repulsion, adhesion, marking, lubricity, wear resistance.

low-pressure gas glow plasma is mainly used in plasma cleaning applications. Some non-cohesive inorganic gases (Ar2, N2, H2, O2, etc.) are excited at high frequency and low pressure to produce various active particles including ions, excited molecules, free radicals, etc. Generally in plasma cleaning, the activated gas can be divided into two categories, one is insert gas plasma (such as Ar2, N2, etc.). Another type of plasma is reactive gas (such as O2, H2, etc.). These active particles cam react with the surface material in the following process : ionization - gas molecules - excitation - excited molecules - cleaning - activation of the surface.

At present, the trend of assembly technology is that SIP, BGA and CSP package make semiconductor devices develop towards modularization, high integration and miniaturization. In such a packaging and assembly process, the biggest problem is the organic contamination of the binding filter and the oxidation film formed in the electric heating. Due to the presence of contaminants on the bonding surface, the bonding strength of these components decreases and the potting strength of resin decreases after encapsulation, which directly affects the assembly level and development of these components. In order to enhance and improve these assembly of these components, we are trying every means to deal with.

The principle of plasma production is as follows :

As can be seen from the figure above, a set of electrodes is applied with a radio frequency voltage (the frequency is about tens of megahertz), and a high-frequency alternating electric field is formed between the electrodes. Under the excitation of the alternating electric field, the gas in the region generates a plasma. The active plasma has the dual effect of surface physical bombardment and chemical reaction on the object to make the material on the surface of the object to be cleaned into particles and gaseous materials, which are discharged by vacuum to achieve the purpose of cleaning.

The cleaning process of plasma cleaning treatment can be divided into two processes in principle.

Process 1 : removal of organic matter

The first is to use the principle of plasma to activate the gas molecules :

O2→ O + O+2e-, O+ O2 → O3, O3 → O + O2

Then, O and O3 are used to react with organic matter to achieve the purpose of excluding organic matter.

Organics : + O, O3→ CO2 + H2O

Process 2 : surface activation

The first is to use the principle of plasma to activation the gas molecules :

O2→ O + O+2e-, O+ O2 → O3, O3 → O + O2

Then , the surface activation of O and O3 oxygen-containing functional groups is used to improve the adhesion and wetting properties of materials, and the reaction is as follows :

R•+O•→RO•

R•+O2→ROO•