In 1877, the first report on the ability of solar radiation to kill bacteria in the medium opened the prelude to the research and application of UV disinfection.

In 1901, mercury lamps began to be used as artificial ultraviolet light sources;

In 1910, in Marseilles, France, the UV disinfection system was first used in the production of urban water treatment, with a daily processing capacity of 200 m3/d.

In about 1911, a groundwater source water plant in Rouen, France, was also UV disinfected.

In 1916, the United States built the first UV disinfection system for the disinfection of domestic water for 12,000 residents in Henderson, Kentucky; In the following years, UV disinfection technology was also adopted in places such as Siberia, Ohio, and Holden, Kansas.

In 1987, in Georgia, about 13,000 inhabitants developed symptoms of enteritis, and cysts of Cryptosporidium were found in tap water. Cases of human cryptosporidiosis have also been found in China, and some other provinces and cities have reported some cases. In patients with diarrhea, the detection rate of Cryptosporidium was 13.3%. In the reference water treatment system where the epidemic occurs, the disinfection process uses chlorination disinfection methods (including chlorine gas, sodium hypochlorite, chlorine dioxide and chloramine). The chlorination disinfection system is tested to operate normally and sufficient chlorine is saved and contacted time. Numerous facts and studies have shown that traditional chlorination methods do not provide sufficient doses to ensure safe water supply to drinking water when cryptosporidiosis is invaded. From 1887 to 1930, the production technology of UV disinfection systems has been initially developed. People have a basic understanding of the disinfection mechanism, and UV disinfection technology has begun to be applied to production practice.

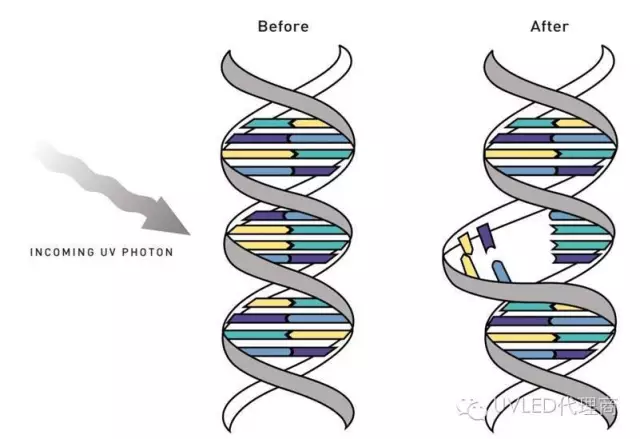

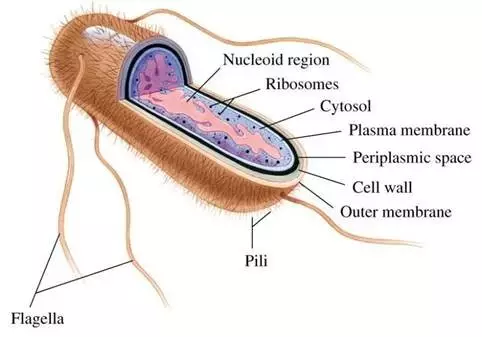

UV disinfection is a serious and century-old scientific conclusion. In early 1903, Danish scientist Niels Ryberg Finsen (1860-1904) won the Nobel Prize for discovering that ultraviolet light can kill the TB virus. Further research by scientists has confirmed that deep UV can break up the DNA or RNA gene chains of bacteria, making them unreproducible and thus killing bacteria. Deep UV sterilization has the following characteristics : its sterilization process is a physical destruction process, so no accessory crops are produced. The sterilization process is not affected by temperature, concentration, activity and other chemical equilibrium conditions. And non-toxic, residues, odor-free, all bacterial cell walls and viral protein shells have no protection against ultraviolet light. Ultraviolet light causes uniform damage to DNA and RNA, and does not require replacement of drugs, and does not require the use of combinations of agent particularly suitable for disinfecting air, water and body surface. The germicidal principle of deep ultraviolet (250-280nm) is different from that of shallow ultraviolet (320-400nm). The UV kills bacteria by destroying their proteins. At the same dose, the deep UV kills thousands of times more bacteria than the UV.

Mechanism of UV LED Disinfection :

Ultraviolet ray is a kind of light wave with high energy, which cannot be recognized by the naked eye. Its wavelength is less than 400nm, and it exists on the outer side of the visible spectrum ultraviolet ray, so it is called ultraviolet ray.

According to the wavelength :

UVA(320nm~400nm)

UVB(275nm~320nm)

UVD(100nm~200nm)

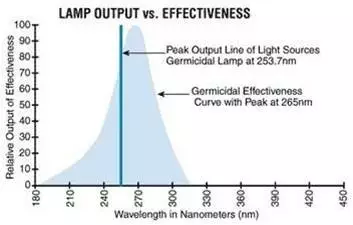

Four bands, of which three bands A, B and C are also called disinfection ultraviolet. The band A, B and C all have certain disinfection effect, especially the band C has the best disinfection effect. Quantum theory holds that light, a special form of matter motion, is a stream of particles that are unconnected. Each UV photon with a wavelength of 253.7nm has an energy of 4.9eV.

The sterilization of water by UV line is mainly the maximum absorption wavelength (254nm) of nucleic acid (DNA). DNA can absorb high-energy ultraviolet radiation, causing the dislocation of adjacent bases to form pyrimidine dimer. Inhibition of nucleic acid replication and protein expression, leading to apoptosis.

Ultraviolet germicidal UV light wavelength is 253.7nm ultraviolet radiation, the most easily absorbed by bacterial and viral proteins, nucleic acids, can make the protein denaturation dissociation, nucleic acid of thymine dimer formation, damage DNA and RNA structure of various viruses and bacteria, and within a few seconds to kill bacteria and viruses, bactericidal efficiency is as high as 99%, can kill the bacteria other disinfecting methods sterilization.

1.Bacteria (more than 18 kinds) : E. coli, bacillus, escherichia coli, clucella, tuberculosis, neisseria coccus, salmonella, etc.

2.Mold (more than 8 kinds), such as: penicillium, black mold, hairy mold, big dung fungus;

3.Viral classes (more than 10), such as: hepatitis virus, influenza virus, polio virus and so on.

UV disinfection and sterilization is not a instantaneous sterilization technology, it needs a irradiation time. UV sterilization irradiation dose is the product of the irradiation intensity and irradiation time of the UV lamp irradiated on the surface of object. For example, a UV surface sterilizer with an irradiation intensity of 70uW/cm2 is used to illuminate the surface of an object at close range.The radiation dose selected was 100000uw.s/cm2;The time required for irradiation is: 100000uw.s/cm2 70uW/cm2 = 24 minutes. Therefore, UV sterilization needs a certain “irradiation time” to produce effect.

The Advantages of UV LED Sterilization :

At present, the commonly used disinfection methods include : chlorine gas, chlorine dioxide, ozone, ultrasound, etc.. But all of them have more or less disadvantages. Therefore, how to meet the new drinking water standards, optimize the water supply process and speed up technical innovation are also the practical problems faced by many water supply enterprises.

UV LED, a new type of ultraviolet light source, has a strong advantage over traditional gas ultraviolet light source such as mercury lamp and hernia lamp. Its main features are as follows :

1.The opening and closing times do not affect the service life. The intensity of ultraviolet radiation of conventional mercury lamp decreases with the increase of opening times and ignition time.

2.Long service life, over 20,000 hours, the life of traditional ultraviolet light is 100-1000 hours.

3.High efficiency and energy saving, the photo-electric conversion efficiency of traditional ultraviolet light source is the highest 60%.

4.The spectrum is concentrated, the ultraviolet light accounts for more than 98% of all optical output, without the infrared radiation provided by the traditional light light source.

5.Small size, only 0.1 cm3 volume, can be assembled into various types of lamp arrays at will, and applied to different requirements.

6.The main crest stenosis was single : over 90% of the light output was concentrated in the range of + / - 10nm near the main crest.

7.Dc low-voltage drive : suitable for portable UV equipment.

8.The output power is stable and continuously adjustable.

9.Instantaneous light emission : no preheating time is required, and the response time is microsecond.

10.Environmental protection : no mercury, no heavy metal pollution.

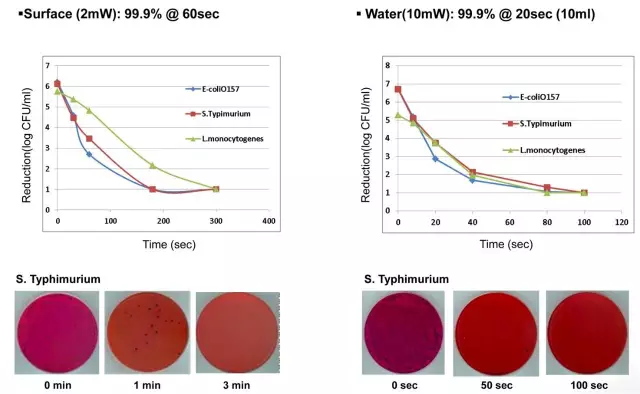

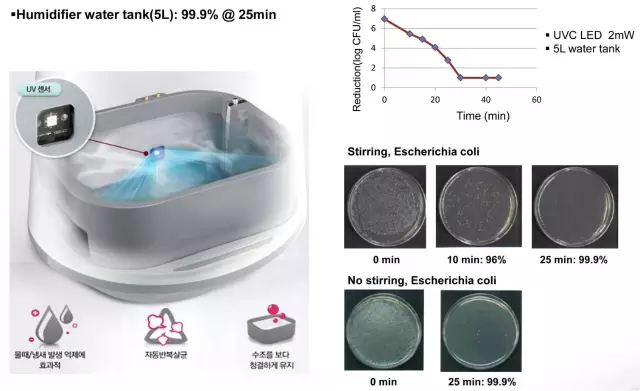

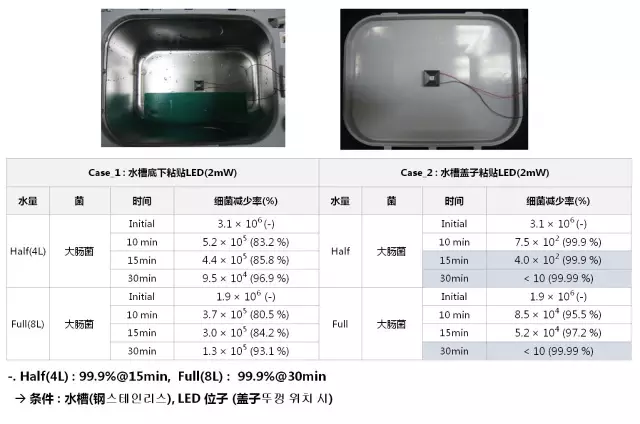

LG Innotek original factory UVC LED 278nm water treatment test date :

LG 3mW 6060 PKG 278nm domestic laboratory water treatment test :

Experimental Objective :

The germicidal effect of 3mW power in the range of 1 - 2 cm2 at different time was tested. Experimental consumables and instruments.

Experimental Consumables and Instruments :

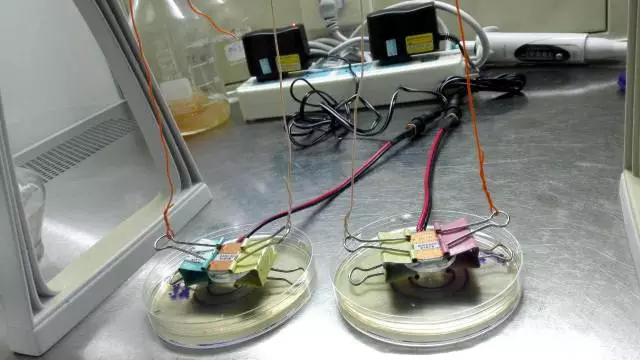

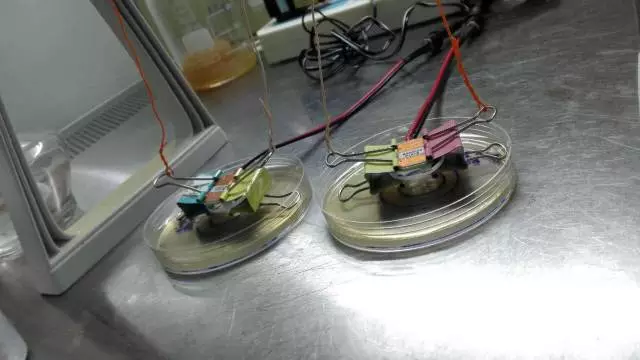

LG UVC LED 3mW 278nm, nutrient AGAR, sterile super clean, 37℃ constant temperature incubator, stents, sterile saline solution

Experimental Method :

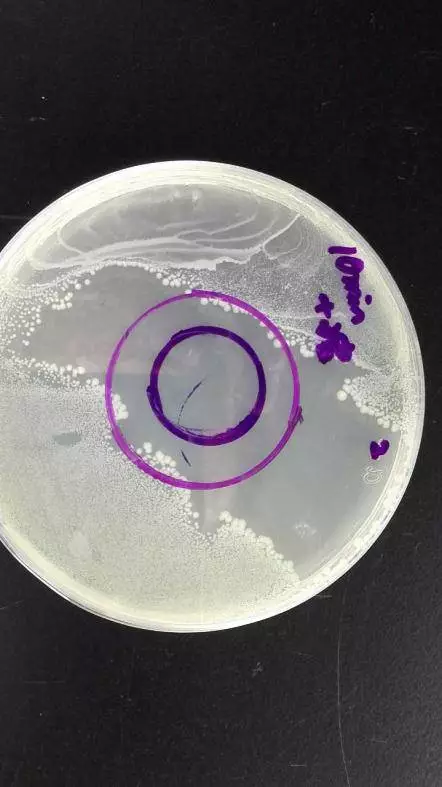

1.Nutrient AGAR powder dissolves, high pressure sterilization, cool to 46℃ nutrient AGAR prudential injection AGAR, about 15 ml and rotation, mixed evenly. After the AGAR has solidified, turned the plate and wait for use.

2.The large intestine rods were diluted to the appropriate concentration with sterile physiological saline, and appropriate amount of bacteria solution was added to AGAR plate surface and the bacteria rods were spread evenly.

3.Set up four sections, as described below :

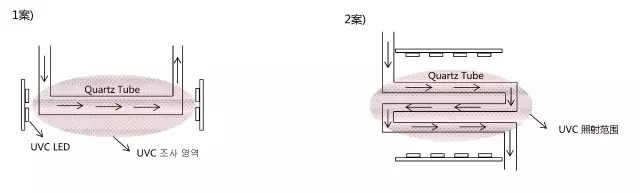

3mW LED + quartz glass module lighting

3mW LED + quartz - free glass module

Positive Control Group

3mW LED + quartz glass module 2 min lighting

3mW LED + quartz glass module 5 min lighting

3mW LED + quartz - free glass module 5 min lighting

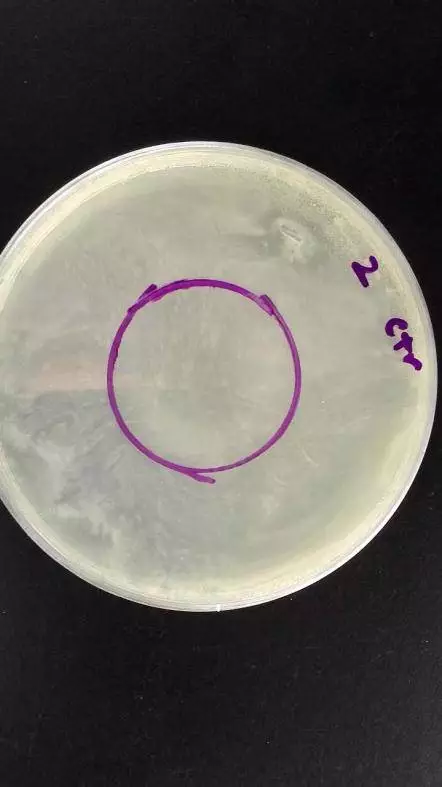

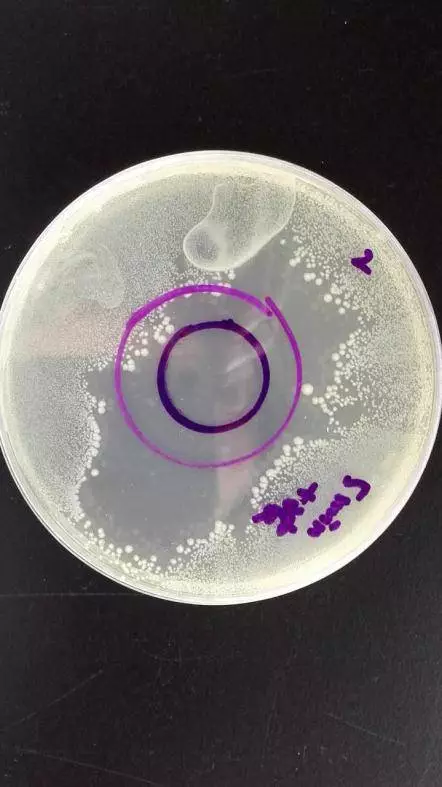

Conclusion :

LG Innotek UVC LED 3mW 278nm for 2 min and 5 min for a range of 1~2 cm2, with a 100% inhibition rate. Among them, there was no significant difference between 3mW+ quartz glass module and 3mW LED+ quartz glass module, and there was no significant difference between 3mW LED+ quartz glass module and 3mW LED+ non-quartz glass module.

Test Method :

GB4789.2-94 (Determination of total population of bacterial colonies by national standard food microphysical examination in People's Republic of China)

SN0168-92 (Count of bacteria colonies of exported food under the standards of import and export commodity inspection industry of the People's Republic of China)

The results showed that LG Innotek UVC LED 278nm water treatment had obvious germicidal effect.

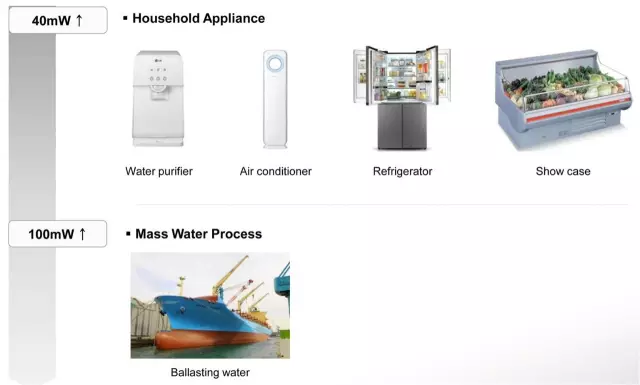

UV LED Application :