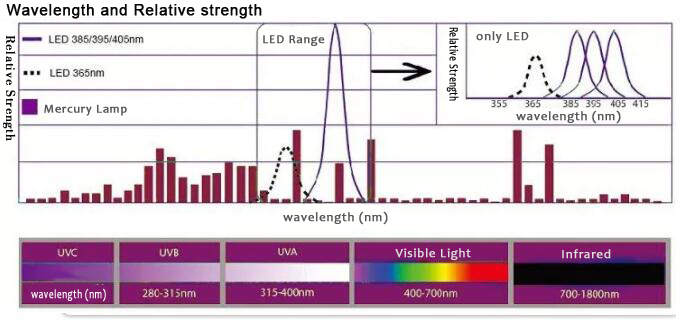

UV LED, namely ultraviolet light emitting diode, is a kind of LED. It is a light source with a peak wavelength of 200nm to 405nm which is integrated in a certain proportion.

UVA wavelength is in 320-390nm, also known as long-wave dark spot effect UV. It has strong penetrate and can penetrate most transparent glass and plastics. With more than 98% of the sun’s long-wave ultraviolet rays reaching the earth’s surface through the ozone layer and clouds, UVA can reach the dermis of the skin, damaging elastic fibers and collagen fibers that tan our skin. The UVA ultraviolet light with a wavelength of 360nm conforms to the photolytic response curve of insects, and can be used to make a trap lamp. UVA of the wavelength of 300-420nm can pass through the special colored glass lamp tube that is completely cut off from visible light, and only emit near-ultraviolet light with the center of 365nm, which can be used for ore identification, stage decoration, banknote inspection and other places.

UVB wavelength is in 280-320nm, also known long-wave red spot effect UV. The shorter part og the wavelength is absorbed by the transparent glass. The medium-wave ultraviolet radiation contained in sunlight is mostly absorbed by the ozone layer. UVB rays have erythema effect on the human body, can promote the mineral metabolism and vitamin D formation in the body, but long-term or excessive irradiation will make the skin suntan, and cause redness and peeling. UV health lamps, plant growth lamps emit a special violet glass (which does not pass through the light below 254nm) and phosphor powder with a peak of around 300nm.

UVC wavelength below 280nm, also known as short-wave sterilization UV. It has the least penetrating power, unable to penetrate most transparent glass and plastics. The short-wavelength ultraviolet light contained in sunlight is almost completely absorbed by the ozone layer. Short-wave ultraviolet (UVB) radiation can cause burns to the sin in a short period of time. Prolonged intense exposure can also cause skin cancer. UV lamp sterilization is UVC short-wave UV.

UVD band, with a wavelength of 100-200nm, also known as vacuum ultraviolet.

UVV band is over 390nm.

Principle :

1.UV LED luminescence mechanism : the terminal voltage of PN junction constitutes a certain potential barrier. When the positive bias voltage is added, the potential barrier drops, and most carriers in the P and N zones diffuse to each other. Since the electron mobility is much greater than hole mobility, a large number of electrons will spread to the P region, forming the injection of a few carriers in the P region.These electrons recombine with holes in the valence band, and the resulting energy is released in the form of light energy.That's how the PN junction glows.

2.UV LED luminous efficiency : generally called the external quantum efficiency of a component, it is the product of internal quantum efficiency of the component and extraction efficiency of the component. The so-called internal quantum efficiency of the component is actually the electrooptical conversion efficiency of the component itself, which is mainly related to the characteristics of the component itself (such as energy band, defect, impurity of the component material), its barrier crystal composition and structure. The extraction efficiency of the component refers to the number of photons produced inside the component, which can be measured outside the component after being absorbed, refaced and reflected by the component itself. Therefore, the factors of extraction efficiency include the absorption of component material itself, the geometry of component, the refractive index difference of the component and packaging material, and the scattering characteristics of the component structure. The product of the internal quantum efficiency of the component and the extraction of the component is the luminescence effect of the whole component, which is the external quantum efficiency of the component. Early component development focused on improving its internal quantum efficiency, by improving the barrier is the main method of crystal quality and change of crystal structure, that is not east to convert electrical energy into heat energy, and thus improve the luminous efficiency of UV LED indirectly, thereby can obtain 70% internal quantum efficiency, the theory of but the internal quantum efficiency is almost close to the theoretical limit. In such a situation, it is possible to improve the total amount of light by improving the internal quantum efficiency of the component, so improving the extraction efficiency of the component becomes an important research topic. The main methods are : the change of grain shape, TIP structure and surface coarsening.

3.UV LED photometric characteristics : current control devices, UI curve with load characteristics similar to PN junction, small change of forward voltage caused by forward voltage (exponential level), small reverse leakage current, and reverse breakdown voltage. In practical use, select. The positive voltage of UV LED decrease with increasing temperature and has negative temperature coefficient. UV LED consumes power and some of it is converted to light energy, which is what we need. The rest is converted into heat, causing the junction temperature to rise. The heat (power) given off can be expressed as.

4.Optical properties of UV LED : UV LED provides monochromatic light with a large half-width. Since the energy gap pf the semiconductor decreases with the rise of temperature, the peak wavelength emitted by it increase with the rise of temperature, namely the spectrum red-shift, and the temperature coefficient is +2~3A/. UV LED luminescence L with positive current. As the current increases, so does the luminescence. In addition, luminous brightness is also related to ambient temperature. When ambient temperature is high, composite efficiency decreases and luminous intensity decreases.

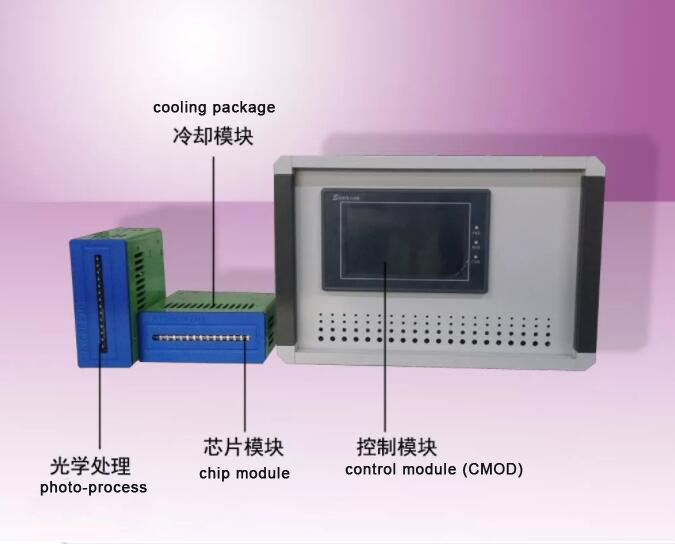

5.UV LED thermal characteristics : small current, LED temperature rise is not obvious. If the ambient temperature is high, the main wavelength of UV LED will shift red, the brightness will decline, and the uniformity and consistency of the light will become worse. In particular, the temperature rise of dot matrix and large display screen has a more significant impact on LED reliability and stability. So cooling design is critical.

6.UV LED life : the aging of UV LED is caused by light decay after long working hours. Especially for high-power UV LED, the problem of high decay is more serious. When measuring the life of UV LED, it is far from enough to take the damage of the lamp as the end point of the life UV LED. The life of LED should be specified by the percentage of the light attenuation of UV LED, such as 35%, which is more meaningful.

7.High power UV LED encapsulation : mainly consider heat dissipation and light output. In terms of heat dissipation, copper based thermal liner is used and then connected to aluminum based radiator. Tin sheet welding is used as the connection between grain and thermal liner. This heat dissipation method has better effect and higher cost performance. In terms of light output, chip flip technology is adopted, and reflection surface on the bottom and side is increased to reflect the wasted light energy, so as to obtain more light with extinction.

Characteristics :

1.No solvents-greenhouse effect

2.It is conductive to environmental protection

3.The workplace is pollution-free

4.Rapid production

5.Curing at room temperature

6.The product has unique performance

7.Save energy

8.Easy to wash

9.Save space

10.High gloss

11.Less waste

12.Method diversity, adaptability and quick product replacement