UV LED is a semiconductor device, but it has its uniqueness. UV LED is a optical, electrical, thermal, and other special device of physics. We believe that the fact is well accepted. Since it has so many physical features, we must take full consideration in our use. So, today, I’m going to do a little bit of my personal understanding of the thermo part.

At present, UV LED luminous efficiency is low. The different brand, the efficiency of the light is not the same. The lower brand, the luminous efficiency is lower. Because the light efficiency is low, the more heat generates. Now, in the terms of UVA, the efficiency of the light is less than 60%, that the 40% is consumed in the form of heat. I believe that you have a clear understanding of the effect of heat on UV LED. I’ll just talk about the effect of the soldering process on the heat of UV LED.

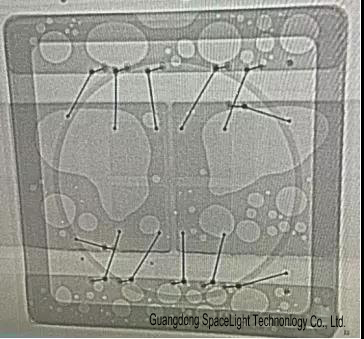

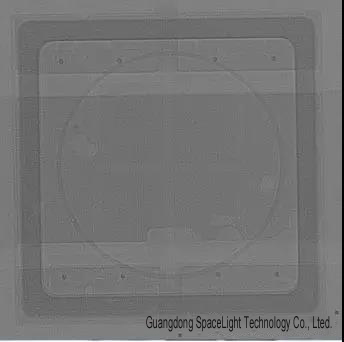

There are many conditions effecting soldering process, we unify these conditions as the same. But the method of reflow soldering if different. Reflow solder is divided into normal reflow solder and vacuum reflow solder. In the same condition, the solder method only effects the cavity rate of the module. So , what is the cavity rater? The cavity rate is the rate of the cavity area to the unit area used to connect the soft solder between two materials (light source and substrate).

I believe you know well that the cavity rate has a certain effect on the heat dissipation effect. The larger the cavity rate, the greater the thermal resistance, and the worse the heat dissipation will be. Normal reflow soldering, only through homework when the temperature of solder bubbles burst so as to achieve the purpose of reduce the cavity rate. Due to the slow flow of the solder paste, the bubble is locked in between the welding materials too late to burst. However, vacuum reflow soldering, before the high temperature welding, the bubble is expelled, and then the welding. At present, the cavity rate of vacuum solder is one third of normal reflow soldering.

The above test data is through our lab equipment X-RAY test. Through the image, we can can clearly see the difference between the two. In theory, cavity rate truly affect the thermal resistance. So, in practice, we can only be used to verify the temperature. First, we analyze the effect of cavity rate on temperature.

You will accept that, under the same heat dissipation condition, the heat resistance between the light source and the substrate is smaller, and the difference between the two is smaller. Conversely, the greater the temperature difference. Let’s use the test data to verify the conclusion.

|

|

Cavity Rate <10% |

Cavity Rate >30% |

||||||||

|

|

1 |

2 |

3 |

4 |

5 |

1 |

2 |

3 |

4 |

5 |

|

Substrate |

42.8 |

43.2 |

45.2 |

39.2 |

58.6 |

45.2 |

42.9 |

47.1 |

41.9 |

69.5 |

|

Lights |

44.7 |

45.5 |

44.6 |

41.2 |

61.7 |

53.7 |

52.7 |

53.7 |

46.3 |

76.2 |

|

Temperature Difference |

-1.9 |

-2.3 |

0.6 |

-2 |

-3.1 |

-8.5 |

-9.8 |

-6.6 |

-4.4 |

-6.7 |

The data is tested at five points, and the highest temperature is selected in the middle.

It can be seen, the smaller the hole rate, the smaller the temperature difference between the two, conversely, the larger the other. The conclusion is true, which means that the larger the cavity rate, the greater the thermal resistance. Under the condition of poor heat dissipation and high environment temperature, the temperature difference between the two will be greater, and the effect on the light source will be greater.

However, the temperature of light source will have what kind of impact, I believe you must be clear. What’s more, I is to say, only we prepared in each link, can we use the best UV LED performance, and make customers satisfaction to the real end.