Ultraviolet (UV) curing is a process of photo-polymerization that converts liquid into solid by using ultraviolet energy. After absorbing the UV energy, the photo-initiator (PI) produces free radicals, which are cross-linked to the binder (monomer and oligomer) through a polymerization process that can cure or solidify an ink, paint or binder in a matter of seconds.

Since its initial introduction in 1960, UV curing has been used by manufacturers in everything from graphic art printing to car headlamp coatings. In fact, the market for UV curable technologies will continue to grow and replace water-based and solvent-based thermal drying processes due to their higher productivity, better quality and performance, and better environmental value.

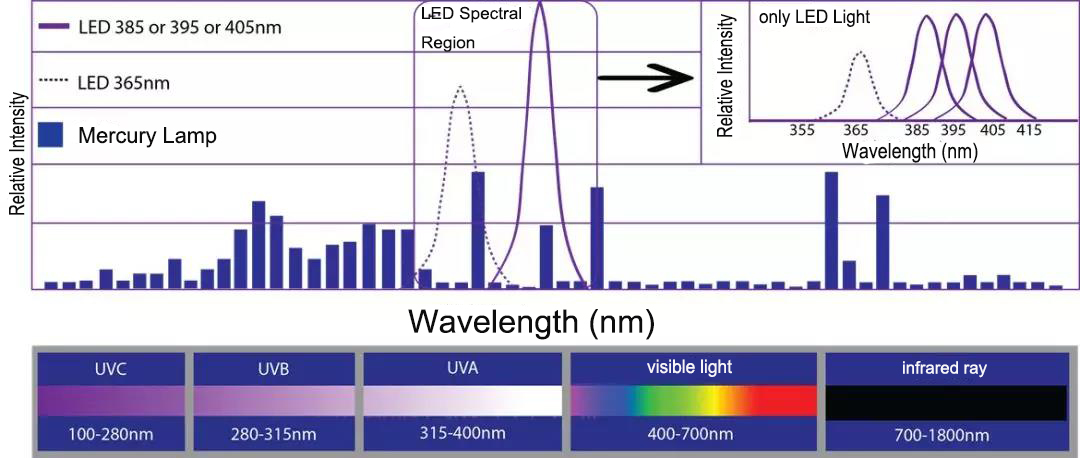

Traditionally, most UV curable technologies excite atoms by generating an electric arc in an ionized gas (usually mercury) chamber, which then decays, producing an arc lamp that generates ultraviolet energy and emits photons. The emitted photons cover a wide spectrum, including some infrared and visible light. However, only about 20% of the spectrum is usually useful for UV curing process.

Basic knowledge of UV curing technology :

UV LEDs are light-emitting diodes (LEDs) for UV curing applications that generate UV energy in a completely different way. When an electric current or electron moves through a semiconductor device called a diode, it emits energy in the form of photons. The specific material used in the diode determines the wavelength of these photons. If a UV LED is used, the output wavelength range is usually very narrow, about +/- 10nm.

High Power UV LED Coating Machine has been commercialized for more than ten years. However, its unique output characteristics require the formulation designer to prepare new UV chemical agents, so as to make full use of the advantages of UV LED UV curing technology. In order to make the UV curing process of inks, coatings or adhesives more effective and efficient, the formulation designer is seeking to overlap the wavelength output of UV lamps through the spectral absorption of PI. Many existing UV formulations developed for typical mercury lamp curing process use board spectrum PI. Usually some spectrum can be absorbed within the output range of UV LED curing process, but most of the PI absorption wavelength range is wasted. Therefore, in order to obtain a more effective curing effect, a new formulation can be developed specially for the UV LED curing technology, so that the wavelength range of long-wave ultraviolet that PI can absorb can be expanded.

Advantages of High Performance UV LED Curing Light Source:

UV curable UV LEDs offer many significant advantages over conventional mercury lamps, including more environmentally friendly (no ozone or mercury emissions), lower substrate heat, and higher energy efficiency. In addition to these advantages, UV LED UV curing technology is very suitable for the field of process control performance, and can reduce product downtime, which is necessary to meet the strict requirements of the end user. UV LED UV curing technology also provides more accurate bonding because it ensures that components are positioned and aligned more precisely and then the adhesive is solidified in just a few seconds.

Typically, electronics manufacturers see a 5-20% improvement in manufacturing efficiency after using Hand-held Ultraviolet Curing Light. In most cases, UV chemistry provides improved curing properties and functions compared to traditional water-based or solvent-based chemicals. For example, UV coatings have excellent scratch resistance, are widely used in adhesion and coating applications for electronic displays, and have excellent optical properties, such as reducing reflections and improving readability, even in the presence of sunlight.

In view of the excellent shape, small size and light weight of UV LED UV curing lamp, it is very easy to design for manufacturing equipment, and through the use of industry standard PLC interface can also achieve simple control. In most cases, because of its high curing rate, manufacturers can automate batch processing, resulting in significant productivity gains. In addition, due to the small of many electronic components, the spotlights and light tubes of UV LED UV curing lamps are ideal for curing areas up to 10 mm in diameter.

Chemical Agent of UV LED UV Curing Technology :

UV chemicals for electronic applications typically include acrylates, silicones or epoxies, of which acrylates are preferred by manufacturers due to their faster curing rate. Many formulations are in the form of single component, making them easy to handle and coat. Most UV preparations are 100% solid, do not cause solvent emissions, and can provide different levels of viscosity according to specific application requirements. The shelf life of these formulations ranges from six months to several years. For some UV formulations, especially those used for adhesion or encapsulation, where UV energy cannot reach any location due to the presence of shaded areas, the dual curing principle is needed to achieve better curing effects, such as UV heating or wet curing. Ultraviolet adhesive can be used to adhere different materials, such as metal, glass and plastic, by using a syringe precision point coating.

Application in UV LED Curing Adhesives and UV Coatings :

Many different electronic products use UV LED UV curing technology in the manufacturing process. The growth is mainly due to the development of mobile electronic products favored by a large number of consumers, the miniaturization of components and manufacturer’s and demand for higher productivity.

Customized LED UV Ink Dyring System for Touch Screen :

Compared with arc lamps, UV LED UV curing lamps provide a process flow with higher consistency and reliability in the touch screen manufacturing field, without damage or discoloration of heat sensitive components.

UV LED curing adhesive formulation is usually acrylic or epoxy resin, curing under the UV wavelength of 365nm, with excellent optical properties, such as light transmission, can reduce the reflection, anti-fog, impact and abrasion resistance. UV LED curing adhesive is easy to remove, and has a high elasticity and will not shrink or stretch between layers, so does not cause image distortion.

Customized LED UV Ink Drying System have low heat and can provide curing process operations on demand, which is particularly beneficial to prevent the damage of sensitive components and provide consistent high-speed process. One particular application is OLED edge packaging, which uses epoxy resin and a locally cured UV LED system to provide an accurate and efficient curing process that effectively isolates moisture infiltration.

Newest UV Curing Solution for Miniature Loudspeaker :

The challenge of this products is the need to bond different materials (metal, paper, plastic), reduce the impact of temperature on sensitive components and high speed and high precision requirements. UV LED UV curing technology uses acrylic adhesive ad usually 365nm UV light, can adhesive a reliable and efficient production process. For example, in the adhesion of voice coil and diaphragm, the diaphragm is usually made of polyester film, paper or metal, the whole process only takes 2-3 seconds, and the UV LED UV curing machine “cold curing” performance will not damage the fragile diaphragm material.

With UV LED UV curing technology, the production speed of micro speakers can be up to 6000 pieces / hour. To ensure on-time delivery, OEM testing can be performed immediately after curing, eliminating the need to maintain existing inventory.

Low Temperature UV Curing Light Source Adhesive Mobile Telephone :

UV LED UV curing technology is very suitable for assembling and painting mobile phone camera module, lens, headset, microphone and shell. UV LED UV curing light can maintain consistent output in mass production for a long time, with low heat output, and avoid the damage of sensitive components, making UV LED UV curing technology become an effective solution in the field of mobile phone component assembly. In addition, UV LED UV curing lamps have the characteristics of small size and high power, which can be easily integrated into the efficient manufacturing process. Currently, the assembly of compact phase camera modules in mobile phones uses Professional UV LED UV curing technology to bond micro components. To connect the lens holder to the image sensor, UV LED UV curing technology uses an automated system that precisely coats the sensor housing with UV binders. Then, the lens holder is precisely positioned on the sensor housing by a precise positioning system. Finally, the UV LED UV curing light can cure the adhesive in a few seconds. Due to the high efficiency of UV LED UV curing technology, the productivity of mobile phone components can be up to 900 pieces / hour.

Stabilized UV LED Cuirng Equipment for Bonding Disk Device :

UV LED UV curing technology is ideal for adhesive curing of disk device (HDD) components such as suspension, read / write heads, and head arm components. UV LED UV curing adhesive with low degassing, in a very short curing time can be easily finished drop coating. UV curing technology provides a fast curing viscosity, can be combined with the various parts, at the same time, the coated conductive adhesive will be exposed to high temperature to cure. More recently, the production of the magnetic head gimbaler assembly (HGA) eliminates the need for two different adhesives bu using formulations based on conductive UV LED UV curing technology based on epoxy or acrylic esterification components.

Conclusion for UV LED UV Curing Technology :

UV LED UV curing technology with consistency and stability of the process, while reducing the damage to heat-sensitive components, to ensure that electronic product manufacturers to obtain higher yields and productivity. Since UV curing machine requires only a small space, they can be easily integrated into a small space. UV curing lights do not produce ozone emissions or hazardous mercury waste, so the technology is considered to be the most environmentally friendly and safe UV curing technology available on the market.

Electronic adhesives and coatings suppliers can use formulations that are compatible with UV LED Curing Machine and are widely used in the field of electronic manufacturing due to their ease of accurate processing and coating, as well as their fast processing speed. Many electronics manufacturers have benefited from the use of UV LED UV curing technology to improve their production processes. Touch screens, mobile phones, micro-speakers and disk drives are just a few examples of commercialized applications of UV LED UV curing technology. Manufacturers of electronic products that already use UV curing technology for arc lamps meed to increase productivity, should look at UV LED UV curing technology.