As a carrier of various components and a hub of circuits signal transmission, PCB has become the most important and critical part of electronic information products. Its quality and reliability determine the quality and reliability of the equipment. However, due to the cost and technical reasons, the PCB has a large number of failures in the process of production and application.

For this kind of failure problem, we need some common failure analysis techniques to ensure the quality and reliability of PCB in manufacturing. This passage summarizes ten failure techniques for reference.

1.Appearance Inspection

Appearance inspection is that visual inspection or use of simple instruments to inspect the appearance of PCB by tools of stereoscopic microscope, metalloscope and even magnifying glass, and to look for lost parts and related physical evidence. The main function is failure localization and preliminary judgement of Copper Base PCB failure mode. The appearance inspection mainly checks the pollution, corrosion, the position of the detonation board, the wiring of the circuit and the regularly of failure, whether the batch or individual is always concentrated in a certain area and so on. In addition, a lot of PCB failure is found after assemble PCBA, whether the assembly process and the influence of process materials lead to the failure, which is needed to carefully check the failure characteristics of the area.

2.X-Ray Fluoroscope

For those parts, that can not be inspected through the appearance and the hole internal and other internal defects of PCB, we have to use X-Ray fluoroscope to check. X-ray fluoroscope is to use different material thickness or different material density to the X-ray absorption or though the different principle of the rate of imaging. This technique is used to check the defects inside the PCBA solder joints, the internal defects of the holes, and the positioning of the defect solder joints of BGA or CSP devices. The resolution of the current industrial X-ray equipment can achieve a micron, and is from 2D to 3D imaging equipment, even five dimensions (5D) equipment used for inspection of packaging, but this kind of 5D X-ray system is very valuable, rarely has practical application in industry.

3.Slice Analysis

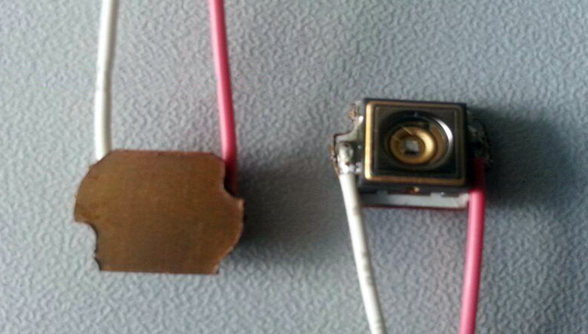

Slice Analysis is the process of the obtaining the cross section structure of PCB by means of sampling, inlaying, slicing, polishing, corrosion and observation. Through slice analysis, we can get rich information about the micro-structure of PCB (through hole, coating etc.), which can provide a good basis for the next step of quality improvement. But the method is destructive. Once sliced, the sample must be destroyed. Meanwhile, this method requires a high level of legal requirements, and it takes a long time to make a sample, which needs a skilled technician to complete. The detail slice operation process is required to refer the process of IPC standard IPC-TM-650 2.1.1 and IPC-MS-810.

4.Scanning Acoustic Microscope (SAM)

Currently, the C mode ultrasonic scanning microscope is mainly used for electronic encapsulation or assembly analysis. It took advantage of high frequency ultrasound imaging which materials is changed by the resulting amplitude and phase and polarity under the discontinuous interface reflection. The scanning method is to scan the X-Y plane along the Z axis. Therefore, the scanning acoustic microscope can be used to detect components, materials, internal defects of PCB and PCBA, including cracks, layers, inclusion, and holes, etc.. If the frequency width of the scan acoustics is sufficient, the internal defects of solder joints can be detected directly.

The typical scanning acoustic image is a alert color of red indicating the presence of a defect. Because the large number of plastic packaging components are used in SMT process. A large amount of wet reflux is produced, which the moisture-absorbent plastic sealing device will appear in the internal or substrate layer cracking phenomenon when the higher lead-free process temperature is returned. In the high temperature of lead-free process, ordinary PCB will often appear. At this point, the scanning acoustic microscope highlights its special advantages in multilayer high density PCB nondestructive testing. However, the obvious detonation plate can be detected by visual appearance alone.

5.Microscopic Infrared Analysis

Microscopic infrared analysis is the method of combining infrared spectra with microscope. It uses different materials (mainly is organic compounds) to absorb different infrared spectra, analyzes the chemical composition of the materials, combines with microscopy which makes visible light with infrared light. As long as you are in the visible field, you can look for trace organic pollutants.

If there is no microscopy, usually the infrared spectrum can only analyze a sample with a large sample size. In the electronic process, a lot of situation is that trace pollution can lead the poor solder-ability of pads or leads of PCB. As you can image, it is difficult to solve the process problem without the infrared spectrum of microscope. The main purpose of the micro-infrared analysis is to analyze the organic pollutants on the surface of weld or solder joints, analyze the cause of corrosion or weld-ability.

(Please continue to read [PCB Failure Analysis Technique Complete(2)])