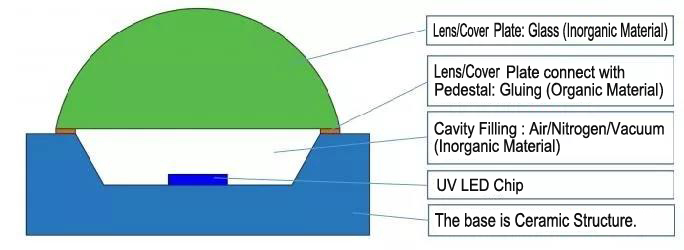

The board is welding UV LED Light Source on Copper Base PCB. The structure of light source is 3535. Through analysis, the base board of light source is ceramic structure. The material of lens is glass. Its combination of lens and ceramic substrate is fixed by organic material (glue).

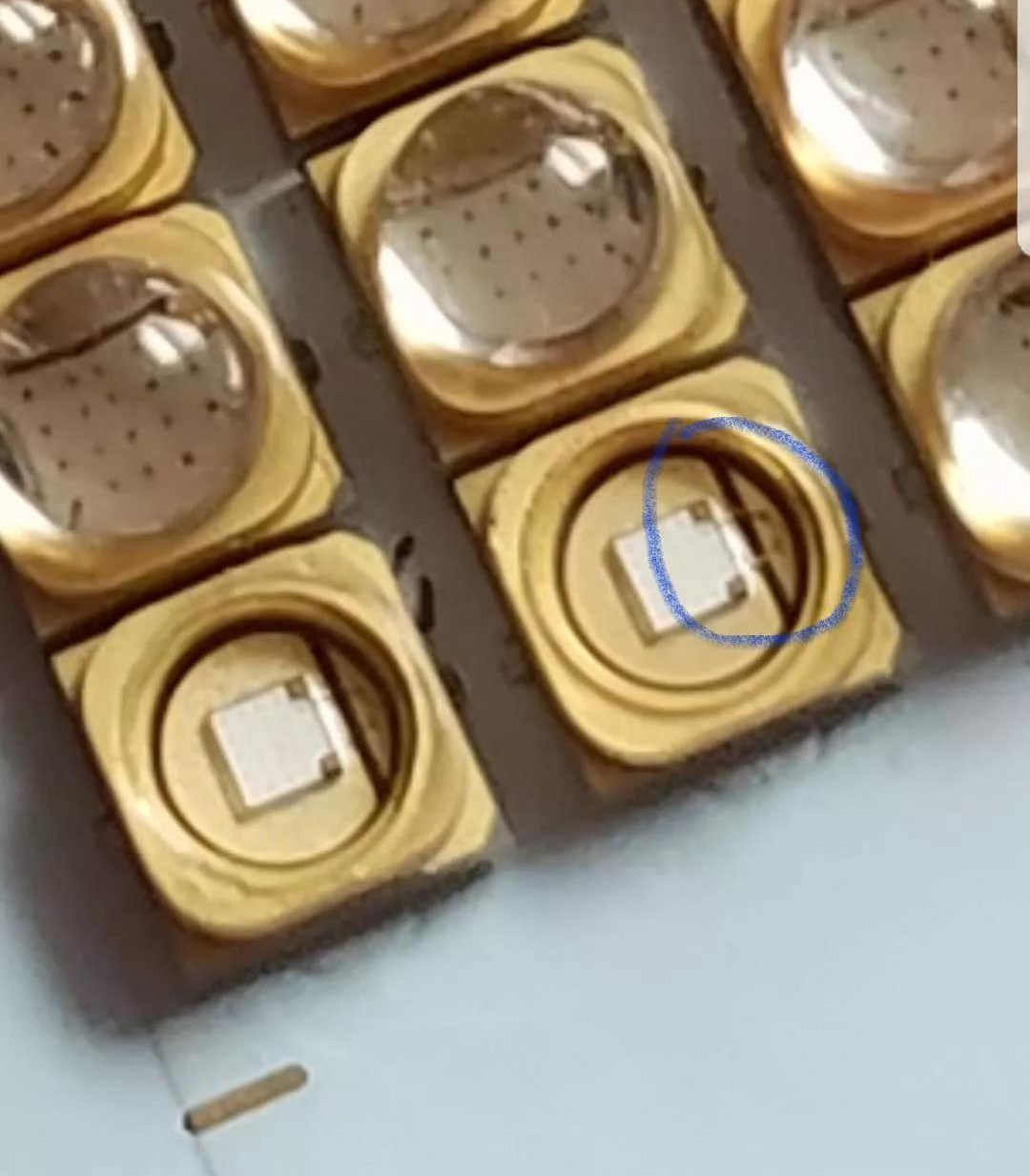

The black sign is lens, the purple sign is light source. Obviously, there are two light source without lens, and only one lens in the sideward. This is where the client had a lens coming off in the early days. The client showed us that lens dropped when you touch gently. So, under the mode of encapsulation, are you very worried when you use it?

However, this mode of encapsulation, due to a certain distance between the chip and the lens, do not have the phenomenon of dead light when the lens fall off.

Please attention to the blue circle. Whether you can see obviously that the gold line between the chip and the ceramic substrate is intact. So, does it have an effect on the application of products? Therefore, I need to explain. After falling the lens, the product has an effect on performance of the product.

First, what does the effect of the lens show? I’m sure you know. The lens is used to make the UV LED Light better focusing, and to achieve a certain amount of light power. So, when the lens fell off, the light power will definitely lose a lot.

Secondly, why should LED have certain air tightness? The electrodes of the chip and the ceramic substrate are made of metal. Generally speaking, the material is gold or silver. As the link between the chip and the ceramic substrate is gold. So, when the metals are lighting, because of the thermal environment, do they oxidize faster? What about if they are in a humid environment? What does they happen after oxidation? Whether the light power is reduced again, they may even fail.

UV LED as a special light source at present. The manufacturer of UV LED Light Source should consider the problems in the application. The real thing is to make the product perfect, that the application can be less problematic and even not go wrong. Only in this way, UV LED can have a better development.