UV LED or Ultraviolet Light Emitting Diodes, are semiconductor devices that directly convert electrical energy into ultraviolet light. Working temperature is usually below 100℃, with long service life, high luminous efficiency, low power consumption, no thermal radiation and other characteristics. UV LED in PCB, microelectronics, medical devices, optics, optical communication and other industries have a wide range of applications and markets.

Mercury is the only liquid metal at room temperature. Mercury vapor is highly toxic and is listed as a global pollutant by the United Nations environment program. Mercury can also enter the human body through the respiratory tract, esophagus and skin, causing harm to human health. The mercury lamp tube also has the very big flaw in the recovery, carelessly discarded mercury lamp tube can cause the very big harm to the soil and the underground water source.

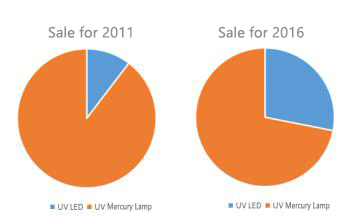

As shown in the figure, in the six yeas from 2011 to 2016, the market share of UV LED increased from 10.4% to 28.1%, and the attention of UV LED kept growing. It is expected that the compound annual growth rate of the global market of UV LED technology will reach 39% by 2020, with high commercial value.

In the electronic lighting, UV LED has the characteristics of low power consumption, small size, long life, is the first choice of all kinds of electronic equipment indicator light, has a certain development space in the service life. In the projection lighting, UV LED can increase the service life, but also changed the projector structure, because of reducing the need for heat dissipation, UV LED in the heat dissipation and noise has a good performance.

Compared with traditional mercury lamp, the advantages of UV LED :

1.Environmental impact. UV LED does not contain mercury, will not produce ozone, safety, environmental protection. Mercury lamps contain mercury, toxic, improper treatment of soil, groundwater and even human health hazards.

2.Life span. UV LED Light is not affected by the open and close times, the service life can reach 20,000-30,000 hours. Mercury lamp tube is high heat, life is only 800-3--- hours.

3.Thermal radiation. Under the UV LED illumination products surface temperature below 5 ° C. Mercury lamp tube, the surface of a product by illuminate rise 60-90 ° C , make the product positioning of displacement, easy to cause bad product.

4.Light up time. UV LED does not need preheating immediately reach 100% power UV output. Mercury lamp tube needs preheating for 10-30 minutes.

5.Calorific value. UV LED working heat is much less than mercury lamp tube. On the one hand to improve the service life of LED, on the other hand to solve the high temperature working environment of workers health damage.

6.Maintenance costs. The maintenance cost of UV LED is almost zero, and the adoption of UV LED curing equipment can save at least 10,000RMB/set of consumption cost every year. Mercury vapor lamp tube has high maintenance cost.

7.Exposure. It adopts high-power UV LED chip and special optical design, the ultraviolet light output reaches the irradiation intensity of 8600mW/m, the radiation luminosity is two times of the tradition mercury lamp, greatly improving the production efficiency.

8.Drive voltage. The driving voltage of UV LED is 5-10V, far less than 100-tens of thousands of volts of mercury lamp tube.

9.Optical design. UV LED with high degree of freedom, miniaturization and lightweight design. Mercury lamp tube more limited.

With the continuous reduction of the cost of Ultraviolet LED, the popularity and application of UV LED is moving towards the field of industrial assembly and daily necessities, and the advantages of UV LED will become more and more obvious.

At present, CREE, Philips and other international LED manufacturers have gradually stopped using aluminum substrate. Ceramic substrate is widely used in LED lighting, sensors and other fields due to its good high-frequency performance and electrical performance, high thermal conductivity, chemical stability and excellent thermal stability and other advantages. It can be said that ceramic substrate quickly occupy the LED market is the trend.