(continuted to The Queations of Technology abput LED Chip, Encapsulation, Illumination (1))

Research Approaches and Technique Course

Basic research: the design of UV LED Mode --- software simulation, analysis and optimization of heat dissipation capacity --- an optical design of LED --- flip chip welding --- apply the phosphor --- LED products molding

1.Selection Criteria for Materials. The related materials should be selected, which must meet certain physical characteristics: such as welding material welding stability, heat conduction and conductive ability of encapsulation material pervious to light quality, heat stability, ability to resist external force and hardness, density, refractive index, homogeneity and stability, water imbibition, turbidity, the highest working temperature for a long time, antistatic, etc.

2.Design and Preparation of Encapsulated Scaffolds

A.Thermal conductivity of thermal conductive substrate material, the material available is aluminum (heat conductivity coefficient is 231W/m.K), copper (385W/m.K), aluminum nitride of ceramic materials (320W/m.K), silicon (191W/m.K), etc..

B.In order to avoid the fusion of two electrodes in eutectic, an insulating intermediate barrier layer with suitable height and size is designed according to the chip size and electrode position.

3.Software simulation, analysis and optimization of structural parameters of UV LED Product model Structure. According to the sample of the design model and the related simulation software analysis the simulation results, by changing the optimization of structural parameters on the LED model, in order to obtain excellent heat dissipation capacity of the optimization model of the LED products.

4.An optical design for LED. Use optical design simulation software (such as TracePro, etc.) to design the flip chip, encapsulation support, mould particle and optical lens.The aim is to achieve the best luminous efficiency.

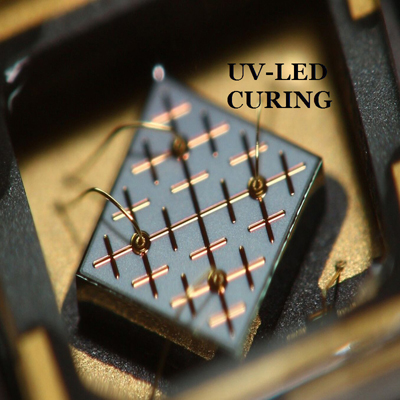

5.The eutectic welding technology of flip chip.

A.At the bottom of the packaging stents, the solder paste bond on the external circuit of positive and negative electrode, the barrier layer insulation layer location cohere with a certain height, in order to avoid the fusion of the two, its height is higher than the height of the solder paste.

B.The positive and negative electrodes of the flip chip are precisely aligned to the circuit that encapsulates the bracket and is attached to the base of the scaffold. Through the eutectic welding process, the temperature is controlled and the flip chip is firmly welded to the bracket.

6.Spray coating technology for phosphors. Considering that the planar phosphor coating process can realize the control of the concentration, thickness and shape of the phosphor soil layer.The uniformity of the distribution of the light spot space and the uniformity of the color and brightness of the tubes are realized.

7.Forming, Molding or lens into products. Based on an optical design structure, a transparent epoxy resin or silicone resin is used to increase the efficiency of optical extraction.

Key Issues that Need to be Addressed

1.It is one of the key technologies to weld the coated chip firmly through eutectic welding technology.It is related to the alignment of electrode, temperature control in eutectic process, solidification strength, chip and roughness of substrate surface.

2. It is ensured that the positive and negative electrodes do not fuse into a key problem during the process.Specifically, how to design and prepare the intermediate barrier layer to realize the effective barrier of positive and negative electrodes.

3.The spraying technology of phosphor powder is mainly the uniformity, thickness and shape of phosphor coating.

4.UV LED Luminous efficiency is an important key in technology, avoiding the damage to the quantum well of the coated chip in the manufacturing process, especially the welding temperature, which leads to the decrease of the luminous efficiency.