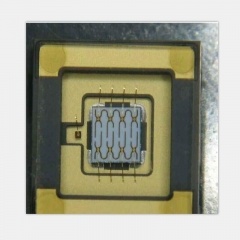

NICHIA UV LED NVSU233B is high power UV LED light beads, made of hard glass material, 365nm.

model no. :

NVSU233B D4 U365nm UV LEDBrand:

DSXUVport of dispatch :

SHENZHENPayment :

T/Toriginal region :

CHINANICHIA UV LED NVSU233B D4 U365nm Hard Glass Material

Specification

1.Absolute Maximum Rating

|

Item |

Symbol |

Absolute Maximum Rating |

Unit |

|

|

U365nm |

Forward Current |

I F |

1400 |

mA |

|

Pulse Forward Current |

I FP |

2000 |

mA |

|

|

Power Dissipation |

P D |

5.88 |

W |

|

|

Junction Temperature |

T J |

130 |

°C |

|

|

U385nm |

Forward Current |

I F |

1400 |

mA |

|

Pulse Forward Current |

I FP |

2000 |

mA |

|

|

Power Dissipation |

P D |

5.88 |

W |

|

|

Junction Temperature |

T J |

130 |

°C |

|

|

U405nm |

Forward Current |

I F |

1400 |

mA |

|

Pulse Forward Current |

I FP |

2000 |

mA |

|

|

Power Dissipation |

P D |

5.6 |

W |

|

|

Junction Temperature |

T J |

130 |

°C |

|

|

Allowable Reverse Current |

I R |

85 |

mA |

|

|

Operating Temperature |

T opr |

-10~85 |

°C |

|

|

Storage Temperature |

T stg |

-40~100 |

°C |

|

* Absolute Maximum Ratings at T S =25°C.

* I FP conditions with pulse width ≤10ms and duty cycle ≤10%.

2.Initial Electrical / Optical Characteristics

|

Item |

Symbol |

Condition |

Type |

Max |

Unit |

|

|

U365 |

Forward Voltage |

VF |

IF =1000mA |

3.85 |

- |

V |

|

Radiant Flux |

Φe |

IF =1000mA |

1450 |

- |

mW |

|

|

Peak Wavelength |

λp |

IF =1000mA |

365 |

- |

nm |

|

|

Spectrum Half Width |

Δλ |

IF =1000mA |

9.0 |

- |

nm |

|

|

U385 |

Forward Voltage |

VF |

IF =1000mA |

3.70 |

- |

V |

|

Radiant Flux |

Φe |

IF =1000mA |

1730 |

- |

mW |

|

|

Peak Wavelength |

λp |

IF =1000mA |

385 |

- |

nm |

|

|

Spectrum Half Width |

Δλ |

IF =1000mA |

11 |

- |

nm |

|

|

U405 |

Forward Voltage |

VF |

IF =1000mA |

3.45 |

- |

V |

|

Radiant Flux |

Φe |

IF =1000mA |

1400 |

- |

mW |

|

|

Peak Wavelength |

λp |

IF =1000mA |

405 |

- |

nm |

|

|

Spectrum Half Width |

Δλ |

IF =1000mA |

12 |

- |

nm |

|

|

Thermal Resistance |

RθJS |

- |

3.9 |

5.7 |

°C/W |

|

* Characteristics at T S =25°C.

* Radiant Flux value as per CIE 127:2007 standard.

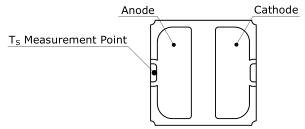

* R θJS is the thermal resistance from the junction to the T S measurement point.

* It is recommended to operate the LEDs at a current greater than 10% of the sorting current to stabilize the LED characteristics.

Ranks

Item

Rank

Min

Max

Unit

Forward Voltage

H1

4.0

4.2

V

M

3.6

4.0

L

3.2

3.6

K

2.8

3.2

Radiant Flux

P11d22

2060

2240

mW

P11d21

1900

2060

P10d22

1740

1900

P10d21

16000

1740

P9d22

1460

1600

P9d21

1340

1460

P8d22

1230

1340

P8d21

1130

1230

P7d22

1040

1130

Peak Wavelength

U405

400

410

nm

U385

380

390

U365

360

370

* Ranking at T S =25°C.

* Forward Voltage Tolerance: ±0.05V

* Radiant Flux Tolerance: ±6%

* Peak Wavelength Tolerance: ±3nm

* LEDs from the above ranks will be shipped. The rank combination ratio per shipment will be decided by Nichia.

Forward Voltage Ranks by Peak Wavelength

Ranking by

Forward Voltage

K

L

M

H1

Ranking by

Peak Wavelength

U365

U385

U405

Radiation Flux by Peak Wavelength

Ranking by

Radiant Flux

P6d21

P6d22

P7d21

P7d22

P8d21

P8d22

P9d21

P9d22

P10d21

Ranking by

Peak Wavelength

U365

U385

U405

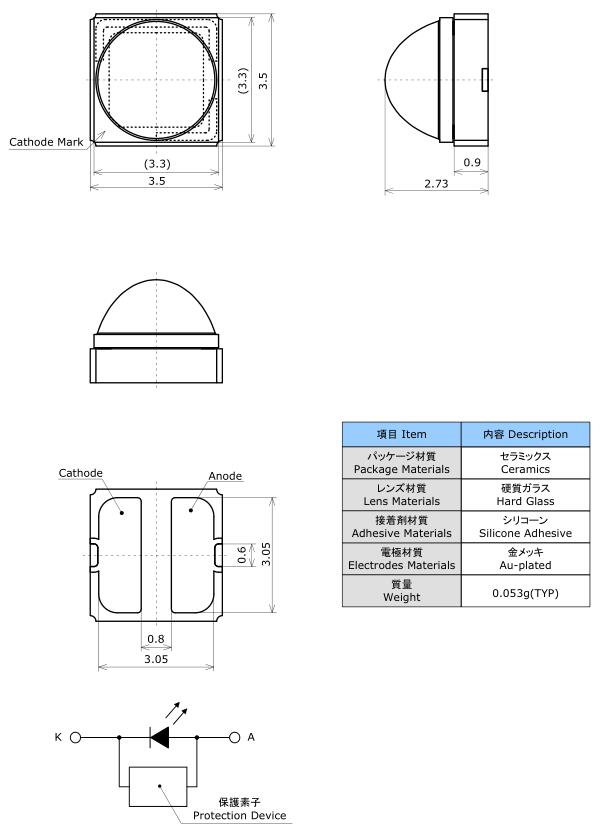

Outline Dimensions (Unit : mm, Tolerance : ±0.2)

Reliability

1.Tests and Results

Test

Reference

Standard

Test Conditions

Test Duration

Failure Criteria #

Units Failed/Tested

Resistance to

Soldering Heat(Reflow Soldering)

JEITA ED-4701

300 301

T sld =260°C, 10sec, 2reflows,

Precondition: 30°C, 70%RH, 168hr

#1

0/10

Thermal Shock

-40°C to 100°C, 15min dwell

100cycles

#1

0/10

High Temperature

Storage

JEITA ED-4701

200 201

T A =100°C

1000hours

#1

0/10

Low Temperature

Storage

JEITA ED-4701

200 202

T A =-40°C

1000hours

#1

0/10

Room Temperature

Operating Life

T A =25°C, I F =1400mA

1000hours

#1

0/10

High Temperature

Operating Life

T A =85°C, I F =800mA

1000hours

#1

0/10

Temperature Humidity

Operating Life

60°C, RH=90%, IF =1000mA

500hours

#1

0/10

Low Temperature

Operating Life

T A =-10°C, I F =1000mA

1000hours

#1

0/10

Vibration

JEITA ED-4701

400 403

200m/s 2 , 100~2000~100Hz,

4cycles, 4min, each X, Y, Z

48minutes

#1

0/10

Electrostatic Discharges

JEITA ED-4701

300 304

HBM, 2kV, 1.5kΩ, 100pF, 3pulses,

alternately positive or negative

#1

0/10

NOTES:

1) R θJA ≈14.0°C/W

2) Measurements are performed after allowing the LEDs to return to room temperature.

2.Failure Criteria

Criteria #

Items

Conditions

Failure Criteria

#1

Forward Voltage(VF )

IF =1000mA

>Initial value×1.1

Radiant Flux(ΦE )

IF =1000mA

<Initial value×0.7

Cautions

1.Storage

Conditions

Temperature

Humidity

Time

Storage

Before Opening Aluminum Bag

≤30°C

≤90%RH

Within 1 Year from Delivery Date

After Opening Aluminum Bag

≤30°C

≤70%RH

≤168hours

Baking

65±5°C

-

≥24hours

● The storage/packaging requirements for this LED are comparable to JEDEC Moisture Sensitivity Level (MSL) 3 or equivalent. Nichia used IPC/JEDEC STD-020 as a reference to rate the MSL of this LED.

● This LED uses a package that could absorb moisture; if the package absorbs moisture and is exposed to heat during soldering, it may cause the moisture to vaporize and the package to expand and the resulting pressure may cause internal delamination. This may cause the optical characteristics to degrade. To minimize moisture absorption in storage/transit, moisture-proof aluminum bags are used for the LEDs with a silica gel packet to absorb any air moisture in the bag. The silica gel beads turn blue to red as they absorb moisture.

● Once the moisture-proof aluminum bag is open, ensure that the LED is soldered to a PCB within the range of the conditions above. To store any remaining unused LEDs, use a hermetically sealed container with silica gel desiccants. Nichia recommends placing them back to the original moisture-proof bag and reseal it.

● If the “After Opening” storage time has been exceeded or any pink silica gel beads are found, ensure that the LED are baked before use. Baking should only be done once.

● This LED has gold-plated electrodes. If the LEDs are exposed to a corrosive environment, it may cause the plated surface to

tarnish causing issues (i.e. solderability). Ensure that when storing LEDs, a hermetically sealed container is used. Nichia

recommends placing them back to the original moisture-proof bag and reseal it.

● To prevent substances/gases from affecting the plated surface, ensure that the parts/materials used with the LEDs in the same assembly/system do not contain sulfur (e.g. gasket/seal, adhesive, etc.). If the plating is contaminated, it may cause issues (e.g. electric connection failures). If a gasket/seal is used, silicone rubber gaskets/seals are recommended; ensure that this use of silicone does not result in issues (e.g. electrical connection failures) caused by low molecular weight volatile siloxane.

● To avoid condensation, the LEDs must not be stored in areas where temperature and humidity fluctuate greatly.

● Do not store the LEDs in a dusty environment.

● Do not expose the LEDs to direct sunlight and/or an environment over a long period of time where the temperature is higher than normal room temperature.

2.Directions for Use

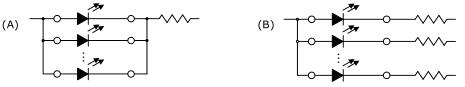

● The circuit must be designed to ensure that the Absolute Maximum Ratings are not exceeded for each LED. The LEDs should be operated at a constant current per LED. In the case of operating at a constant voltage, Circuit B is recommended. If Circuit A is used, it may cause the currents flowing through the LEDs to vary due to the variation in the forward voltage characteristics of the LEDs on the circuit.

● This LED is designed to be operated at a forward current. Ensure that no voltage is applied to the LED in the forward/reverse direction while the LED is off. If the LEDs are used in an environment where reverse voltages are applied to the LED continuously, it may cause electrochemical migration to occur causing the LED to be damaged. When not in use for a long period of time, the system’s power should be turned off to ensure that there are no issues/damage.

● To stabilize the LED characteristics while in use, Nichia recommends that the LEDs are operated at currents ≥ 10% of the sorting current.

● Ensure that transient excessive voltages (e.g. lighting surge) are not applied to the LEDs.

● If the LEDs are used for outdoor applications, ensure that necessary measures are taken (e.g. protecting the LEDs from water/salt damage and high humidity).

● Although this LED is specifically designed to emit invisible light, a small amount of light in the visible region exists in the emission spectrum. Ensure that when using the LEDs for sensors, verification is performed to ensure that the emission spectrum is fit for the intended use.

● If this product is stored and/or used constantly under high humidity conditions, it may accelerate the deterioration of the die; this may cause the radiant flux to decrease. If the LEDs are stored and/or used under these conditions, sufficient verification must be done prior to use to ensure there are no issues for the chosen application.

● Do not design this LED into applications where condensation may occur. If the LEDs are stored/operated in these environments, it may cause issues (e.g. current leaks that cause the radiant flux to decrease).

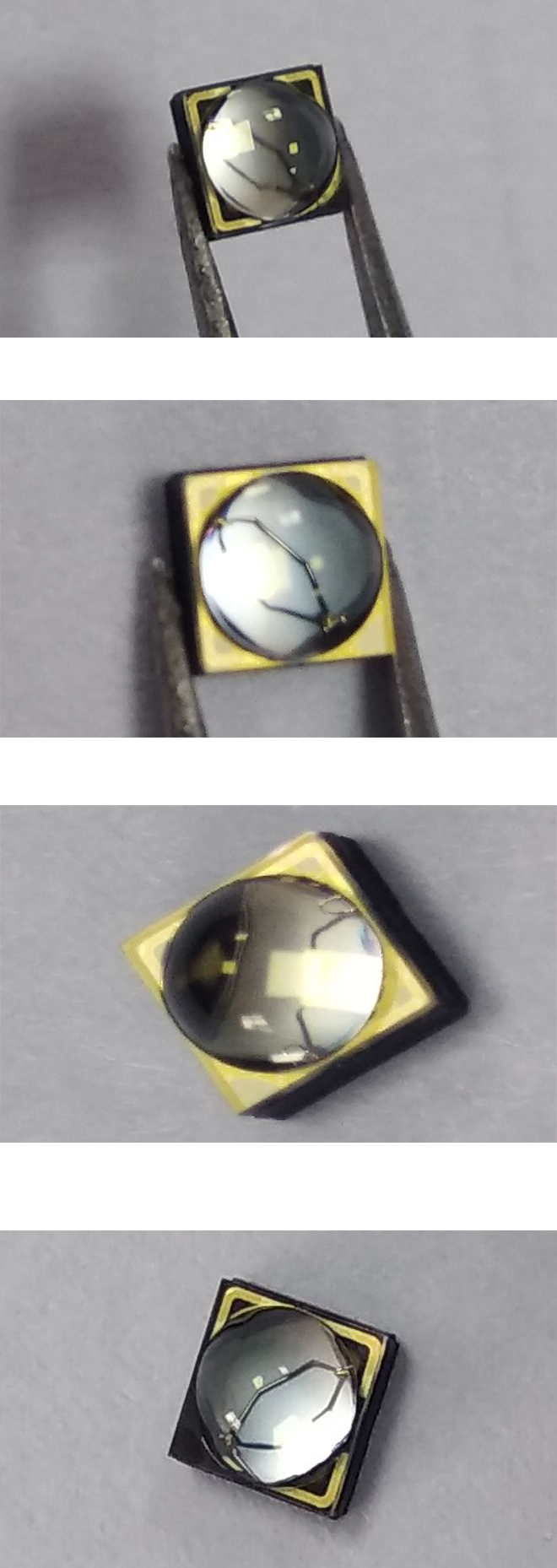

3.Handling Precautions

● Do not handle the LEDs with bare hands:

- this may contaminate the LED surface and have an effect on the optical characteristics,

- this may cause the LED to deform and/or the wire to break causing a catastrophic failure (i.e. the LED not to illuminate).

● When handling the product with tweezers, be careful not to apply excessive force to the glass. Otherwise, The glass can be cut, chipped, delaminate or deformed, causing wire-bond breaks and catastrophic failures.

● Dropping may cause damage to the LED (e.g. deformation).

● Do not stack assembled PCBs together. Otherwise, it may cause damage to the glass cover (e.g. cut, scratch, chip, crack, delamination and deformation) and the wire to break causing a catastrophic failure (i.e. the LED not to illuminate).

4.Design Consideration

● To operate the LEDs, using a copper-core PCB is recommended; this may cause issues (e.g. cracks in the glass cover/solder joints due to thermal stress) depending on the reflow soldering conditions. Ensure that sufficient verification is performed prior to use to ensure that there are no issues with the PCB/soldering conditions for the chosen application.

● If the LEDs are soldered to a PCB and the PCB assembly is bent (e.g. PCB depaneling process), it may cause the LED package to break. The PCB layout should be designed to minimize the mechanical stress on the LEDs when the PCB assembly is bent/warped.

● The amount of mechanical stress exerted on the LED from depaneling may vary depending on the LED position/orientation on the PCB assembly (e.g. especially in areas near V-groove scores). The PCB layout should be designed to minimize the mechanical stress on the LEDs when the PCB is separated into individual PCB assemblies.

● To separate a PCB populated with the LEDs, use a specially designed tool. Do not break the PCB by hand.

● If an aluminum-core PCB is used to operate the LEDs, it may cause thermal stress during operation causing damage to the solder joints (e.g. crack). Ensure that sufficient verification is performed prior to use.

5.Electrostatic Discharge (ESD)

● This LED is sensitive to transient excessive voltages (e.g. ESD, lightning surge). If this excessive voltage occurs in the circuit, it may cause the LED to be damaged causing issues (e.g. the LED to have a reduction in the radiant flux or not to illuminate [i.e. catastrophic failure]).

Ensure that when handling the LEDs, necessary measures are taken to protect them from an ESD discharge. The following examples are recommended measures to eliminate the charge:

- Grounded wrist strap, ESD footwear, clothes, and floors

- Grounded workstation equipment and tools

- ESD table/shelf mat made of conductive materials

● Ensure that all necessary measures are taken to prevent the LEDs from being exposed to transient excessive voltages (e.g. ESD, lightning surge):

- tools, jigs, and machines that are used are properly grounded

- appropriate ESD materials/equipment are used in the work area

- the system/assembly is designed to provide ESD protection for the LEDs

● If the tool/equipment used is an insulator (e.g. glass cover, plastic, etc.), ensure that necessary measures have been taken to protect the LED from transient excessive voltages (e.g. ESD). The following examples are recommended measures to eliminate the charge:

- Dissipating static charge with conductive materials

- Preventing charge generation with moisture

- Neutralizing the charge with ionizers

● To detect if an LED was damaged by transient excess voltages (i.e. an ESD event during the system’s assembly process), perform a characteristics inspection (e.g. forward voltage measurement) at low current (≤1mA).

● Failure Criteria: V F <2.0V at I F =0.5mA

If the LED is damaged by transient excess voltages (e.g. ESD), it will cause the Forward Voltage (V F ) to decrease.

6.Thermal Mangement

● The Absolute Maximum Junction Temperature (T J ) must not be exceeded under any circumstances. The increase in the temperature of an LED while in operation may vary depending on the PCB thermal resistance and the density of LEDs on the PCB assembly. Ensure that when using the LEDs for the chosen application, heat is not concentrated in an area and properly managed in the system/assembly.

● The operating current should be determined by considering the temperature conditions surrounding the LED (i.e. T A ). Ensure that when operating the LED, proper measures are taken to dissipate the heat.

● The following two equations can be used to calculate the LED junction temperature:

1)T J =T A +R θJA ・W

2) T J =T S +R θJS ・W

*T J =LED Junction Temperature: °C

T A =Ambient Temperature: °C

T S =Soldering Temperature (Anode Side): °C

R θJA =Thermal Resistance from Junction to Ambient: °C/W

R θJS =Thermal Resistance from Junction to T S Measurement Point: °C/W

W=Input Power(I F ×V F ): W

● Do not clean the LEDs. If the LED is cleaned, it may cause damage to the package/glass cover causing issues; ensure that if the LEDs are cleaned, sufficient verification is performed prior to use. Additionally, ensure that the solvent being used does not cause any other issues (e.g. CFC-based solvents are heavily regulated).

● Do not clean the LEDs with an ultrasonic cleaner. If cleaning must be done, ensure that sufficient verification is performed by using a finished assembly with LEDs to determine cleaning conditions (e.g. ultrasonic power, LED position on the PCB assembly) that do not cause an issue.

8.Eye Safety

● There may be two important international specifications that should be noted for safe use of the LEDs: IEC 62471:2006

Photobiological safety of lamps and lamp systems and IEC 60825-1:2001 (i.e. Edition 1.2) Safety of Laser Products - Part 1:

Equipment Classification and Requirements. Ensure that when using the LEDs, there are no issues with the following points:

- LEDs have been removed from the scope of IEC 60825-1 since IEC 60825-1:2007 (i.e. Edition 2.0) was published. However, depending on the country/region, there are cases where the requirements of the IEC 60825-1:2001 specifications or equivalent must be adhered to.

- LEDs have been included in the scope of IEC 62471:2006 since the release of the specification in 2006.

- Most Nichia LEDs will be classified as the Exempt Group or Risk Group 1 according to IEC 62471:2006. However, in the case of high-power LEDs containing blue wavelengths in the emission spectrum, there are LEDs that will be classified as Risk Group 2 depending on the characteristics (e.g. radiation flux, emission spectrum, directivity, etc.)

- If the LED is used in a manner that produces an increased output or with an optic to collimate the light from the LED, it may cause damage to the human eye.

● If an LED is operated in a manner that emits a flashing light, it may cause health issues (e.g. visual stimuli causing eye discomfort).

The system should be designed to ensure that there are no harmful effects on the human body.

● This LED emits light in the ultraviolet (UV) region. The UV light from an LED while in operation is intense and harmful; if human eyes are exposed to this light, it may cause damage to them. Do not look directly or indirectly (e.g. through an optic) at the UV light. Ensure that if there is a possibility that the UV light reflects off objects and enters the eyes, appropriate protection gear (e.g. goggles) is used to prevent the eyes from being exposed to the light.

● Ensure that appropriate warning signs/labels are provided both on each of the systems/applications using the UV LEDs, in all necessary documents (e.g. specification, manual, catalogs, etc.), and on the packaging materials.

9.Miscellaneous

● Nichia warrants that the discrete LEDs will meet the requirements/criteria as detailed in the Reliability section within this specification. If the LEDs are used under conditions/environments deviating from or inconsistent with those described in this specification, the resulting damage and/or injuries will not be covered by this warranty.

● Nichia warrants that the discrete LEDs manufactured and/or supplied by Nichia will meet the requirements/criteria as detailed in the Reliability section within this specification; it is the customer’s responsibility to perform sufficient verification prior to use to ensure that the lifetime and other quality characteristics required for the intended use are met.

● The applicable warranty period is one year from the date that the LED is delivered. In the case of any incident that appears to be in breach of this warranty, the local Nichia sales representative should be notified to discuss instructions on how to proceed while ensuring that the LED in question is not disassembled or removed from the PCB if it has been attached to the PCB. If a breach of this warranty is proved, Nichia will provide the replacement for the non-conforming LED or an equivalent item at Nichia’s discretion. FOREGOING ARE THE EXCLUSIVE REMEDIES AVAILABLE TO THE CUSTOMER IN RESPECT OF THE BREACH OF THE

WARRANTY CONTAINED HEREIN, AND IN NO EVENT SHALL NICHIA BE RESPONSIBLE FOR ANY INDRECT, INCIDENTAL OR CONSEQUENTIAL LOSSES AND/OR EXPENSES (INCLUDING LOSS OF PROFIT) THAT MAY BE SUFFERED BY THE CUSTOMER ARISING OUT OF A BREACH OF THE WARRANTY.

● NICHIA DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

● This LED is intended to be used for general lighting, household appliances, electronic devices (e.g. mobile communication devices); it is not designed or manufactured for use in applications that require safety critical functions (e.g. aircraft, automobiles, combustion equipment, life support systems, nuclear reactor control system, safety devices, spacecraft, submarine repeaters, traffic control equipment, trains, vessels, etc.). If the LEDs are planned to be used for these applications, unless otherwise detailed in the specification, Nichia will neither guarantee that the LED is fit for that purpose nor be responsible for any resulting property damage, injuries and/or loss of life/health. This LED does not comply with ISO/TS 16949 and is not intended for automotive applications.

● The customer will not reverse engineer, disassemble or otherwise attempt to extract knowledge/design information from the LED.

● All copyrights and other intellectual property rights in this specification in any form are reserved by Nichia or the right holders who have granted Nichia permission to use the content. Without prior written permission from Nichia, no part of this specification may be reproduced in any form or by any means.

● Both the customer and Nichia will agree on the official specifications for the supplied LEDs before any programs are officially launched. Without this agreement in writing (i.e. Customer Specific Specification), changes to the content of this specification may occur without notice (e.g. changes to the foregoing specifications and appearance, discontinuation of the LEDs, etc.).

High Power UV-LED NVSU333A U365nm 18.9W 3640mW/cm2

High Power UV-LED NVSU333A U365nm 18.9W 3640mW/cm2

NVSU333A UV-LED is widely used in high precision curing, ink curing (printing), bill checker etc. It's also the best way to solidify UV glue.

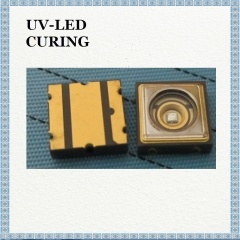

NICHIA UV LED NVSU233B U365nm

NICHIA UV LED NVSU233B U365nm

NICHIA UV LED NVSU233B U365nm is most applied in UV curing, splicing, UV glue, and UV prinying ink curing.

NICHIA NCSU033B 365nm UV LED

NICHIA NCSU033B 365nm UV LED

NICHIA NCSU033B 365nm UV LED can be used for criminal investigation, such as the observation of fingerprint, bloodstain, etc., mineral fluorescence observation, oil cleaning observation, and so on.

NICHIA UV LED NCSU033C U365nm

NICHIA UV LED NCSU033C U365nm

NICHIA UV LED NCSU033C U365nm is Pb-free reflow Soldering application, built-in EDS protection Device, RoHS compliant.

SVC CUN6GF1A UV 365nm 5W High Radiant Flux 1300mW

SVC CUN6GF1A UV 365nm 5W High Radiant Flux 1300mW

The applications of SVC CUN6GF1A UV 365nm 5W High Radiant Flux 1300mW are UV curing, printing, coating, adhesive, counterfeit dection/security, UV torch, fluorescence, photegraphy, dental curing, crime inspection, oil leak detection.

High Power NICHIA UV LED NCSU276A U365nm for UV Curing

High Power NICHIA UV LED NCSU276A U365nm for UV Curing

NICHIA UV LED NCSU276A U365nm requires unique and delicate production process. NICHIA places strict controls from wafer manufacturing to final inspection.